Lösung von Entwässerungsproblemen: Wann Sie das Filtertuch Ihrer Bandfilterpresse aufrüsten sollten

Veröffentlichungsdatum: 21.11.2025

Inhaltsverzeichnis

Bandfilterpressen werden in der Bergbau-, Chemie-, Lebensmittel- und Abwasserbehandlungsindustrie zur Fest-Flüssig-Trennung und Entwässerung eingesetzt. Eine ihrer Kernkomponenten – das Filtertuch – beeinflusst maßgeblich die Entwässerungseffizienz und die Anlagenleistung. Im Laufe der Zeit können Filtertücher jedoch verschleißen, verstopfen oder ausfallen, was zu einer unzureichenden Entwässerung führt. Xurui unterstützt Sie bei der Diagnose von Entwässerungsproblemen mit den Filtertüchern Ihrer Bandfilterpresse und zeigt Ihnen, wann ein Austausch sinnvoll ist.

Die Rolle der Bandfilterpresstücher

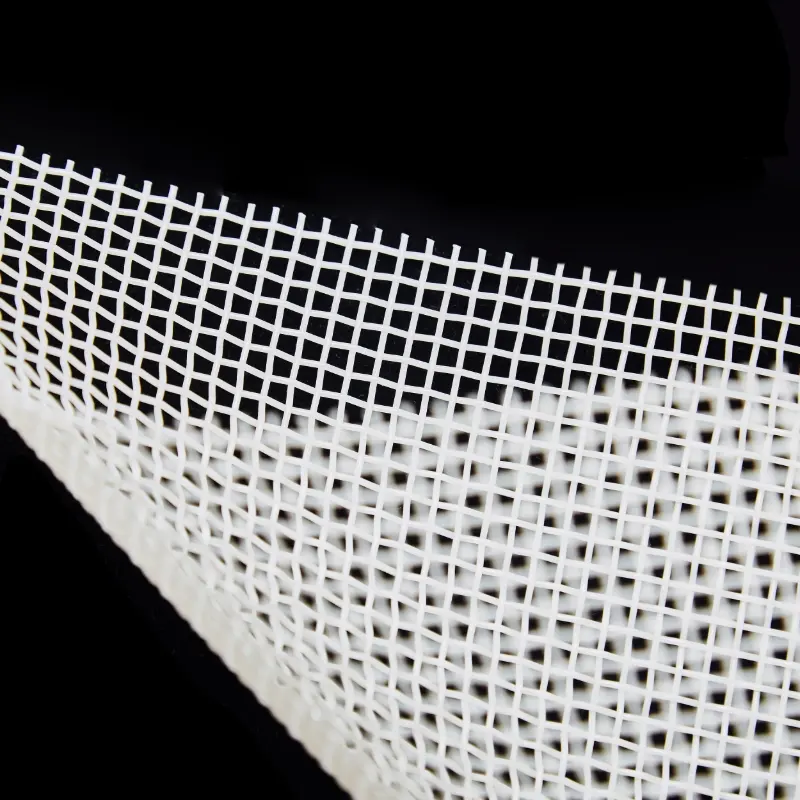

Die Filtertücher von Bandfilterpressen spielen eine entscheidende Rolle bei der Fest-Flüssig-Trennung. Ihre Hauptfunktion besteht darin, Feststoffpartikel mithilfe ihrer Porenstruktur und Oberflächenbeschaffenheit von Flüssigkeiten zu trennen. Material, Dicke und Porengröße des Filtertuchs beeinflussen die Filtrationsleistung direkt. Hochwertige Bandfilterpresstücher kann den Flüssigkeitsrückstand reduzieren und gleichzeitig eine effektive Entwässerung des Filterkuchens gewährleisten, wodurch die Produktionseffizienz verbessert wird.

Mit zunehmender Nutzungsdauer lässt die Leistung des Filtertuchs jedoch allmählich nach, was zu einer weniger effektiven Entwässerung führt. Durch rechtzeitige Erkennung und den Austausch des Filtertuchs lässt sich die Funktionsfähigkeit des Geräts in diesem Fall jedoch wiederherstellen.

Häufige Probleme mit dem Filtertuch von Bandfilterpressen

Schlechte Filtrationseffizienz: Ist das Filtrat trüb oder weist der Filterkuchen bei der Materialverarbeitung in der Bandfilterpresse einen zu hohen Feuchtigkeitsgehalt auf, kann das Filtertuch gealtert und nicht mehr effektiv filtern. Häufige Ursachen sind Oberflächenverunreinigungen oder verstopfte Poren des Filtertuchs.

Verstopfung des Filtertuchs: Während des Betriebs können sich Feststoffe auf der Oberfläche des Filtertuchs der Bandfilterpresse ablagern, was zu Porenverstopfungen und in schweren Fällen zu einer Beeinträchtigung der Filtrationsrate führen kann. Dieses Phänomen tritt typischerweise bei der Verarbeitung feinkörniger Materialien oder ölhaltiger Schlämme auf.

Starker Verschleiß des Filtertuchs: Nach längerem Gebrauch weist die Oberfläche des Filtertuchs deutliche Abnutzungserscheinungen und Beschädigungen auf, was zu einer Verringerung der Filtrationsgenauigkeit führt. Dies tritt besonders häufig im Bergbau oder in Umgebungen mit hoher Betriebsbelastung auf.

Zugverformung von Filtertüchern: Ist die Zugfestigkeit des Filtergewebes unzureichend, kann es sich nach längerem Einwirken hohen Drucks verformen oder brechen, was die Filtrationseffizienz und die Stabilität der Anlage beeinträchtigt.

Wann ist ein Austausch des Filtertuchs in der Bandfilterpresse erforderlich?

Alterung oder Beschädigung des Filtertuchs: Wenn die Oberfläche des Filtertuchs deutliche Risse, Abnutzungserscheinungen oder Brüche aufweist, bedeutet dies, dass es seine ursprüngliche Filterleistung verloren hat. Dann ist es an der Zeit, das Filtertuch durch ein haltbareres, neues Material zu ersetzen. Polyester-Bandpressfiltertuch oder Polypropylen-Filtertuch.

Kontinuierlich abnehmende Filtrationseffizienz: Wenn die Entwässerung nicht den Anforderungen entspricht, das Filtrat trüb bleibt oder der Filterkuchen einen zu hohen Feuchtigkeitsgehalt aufweist, deutet dies darauf hin, dass die Poren des Filtertuchs verstopft sind oder Feststoffe und Flüssigkeiten nicht effektiv trennen können. In diesem Fall kann die Filtrationseffizienz durch den Einsatz von hochporösem Bandfiltertuch oder schlammresistentem Filtertuch deutlich verbessert werden.

Häufiges Reinigen kann die Leistung nicht wiederherstellen: Auch nach der Reinigung lässt sich die Filterleistung des Filtertuchs nicht wiederherstellen. Dies liegt meist daran, dass die Fasern des Filtertuchs stark beschädigt sind und nicht mehr effektiv filtern können. In diesem Fall ist der Austausch des Filtertuchs die einzige Lösung.

Erhöhter Durchsatz oder optimierter Prozess: Wenn der Produktionsbedarf eines Unternehmens steigt und eine höhere Entwässerungskapazität oder eine verbesserte Effizienz der Bandfilterpresse erforderlich ist, kann ein effizienteres Bandfilterpressentuch mit hohem Durchfluss ausgewählt werden, um der höheren Arbeitsbelastung gerecht zu werden.

Wie wählt man das richtige Bandfilterpressentuch aus?

Bei der Auswahl neuer Filtertücher ist es unerlässlich, die spezifischen Einsatzbedingungen und Materialeigenschaften zu berücksichtigen. Folgende Faktoren sind bei der Auswahl von Filtertüchern für Bandfilterpressen zu beachten:

Materialauswahl: Wählen Sie das geeignete Filtertuchmaterial anhand der Eigenschaften des zu verarbeitenden Materials. Polyester-Filtertuch eignet sich beispielsweise für die meisten neutralen Materialien, während Polypropylen-Filtertuch für Umgebungen mit hohen Temperaturen und hohem Säure-/Alkaligehalt geeignet ist.

Porenstruktur: Die Porengröße des Filtertuchs beeinflusst die Entwässerungswirkung. Für Materialien mit größeren Partikelgrößen empfiehlt sich ein abriebfestes Bandfiltertuch mit größeren Poren; für feine Materialien oder Anwendungen, die eine höhere Filtrationsgenauigkeit erfordern, ist hingegen ein Filtertuch mit feineren Poren geeignet.

Korrosions- und Abriebbeständigkeit: Für stark korrosive Umgebungen wie die chemische Industrie oder den Bergbau, korrosionsbeständige BandpressenfiltertücherUm ihre Lebensdauer zu verlängern, sollten Filtertücher aus Polyester oder PVC ausgewählt werden.

Zugfestigkeit und Zugkapazität: Die Zugfestigkeit des Filtertuchs muss den Betriebsanforderungen der Bandfilterpresse unter hohem Druck genügen, um ein Brechen oder Verformen während des Betriebs zu verhindern.

Zusammenfassung

Die Auswahl und Wartung der Filtertücher von Bandfilterpressen sind entscheidend für eine effiziente Entwässerung und einen langfristig stabilen Betrieb der Anlage. Durch die frühzeitige Erkennung von Verschleiß, Verstopfungen oder Alterungserscheinungen und die Auswahl geeigneter Lösungen zur Erneuerung der Filtertücher lassen sich die Filtrationseffizienz effektiv steigern, Anlagenausfälle reduzieren und die Betriebskosten senken. Sollten Ihre Filtertücher Probleme aufweisen, handeln Sie umgehend und tauschen Sie sie schnellstmöglich aus, um eine reibungslose Produktion zu gewährleisten.