Polyester Plain Weave Mesh Conveyor Belts Linear Screen Cloth Conveyor Belts For Drying Mining

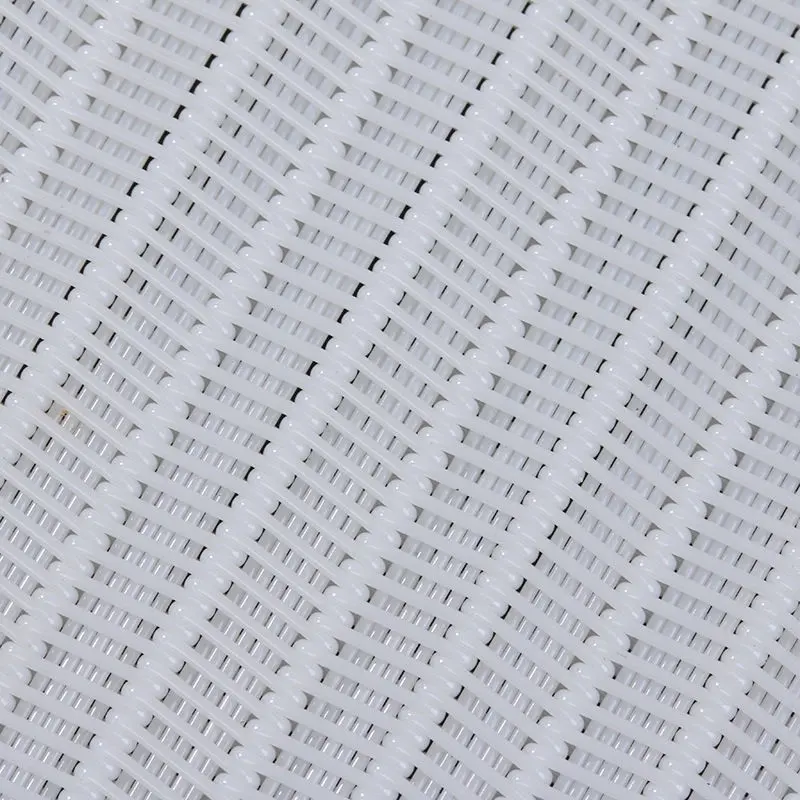

It have the characteristics of tear-resistance, shrink-resistance and abrasion resistance etc. Polyester Monofilament process conveyor belting is available in a wide variety of yarn thicknesses and apertures. Polyester mesh belting is characterised by high reliability, easy handling, thermal and chemical resistance coupled with dimensional stability.

Features

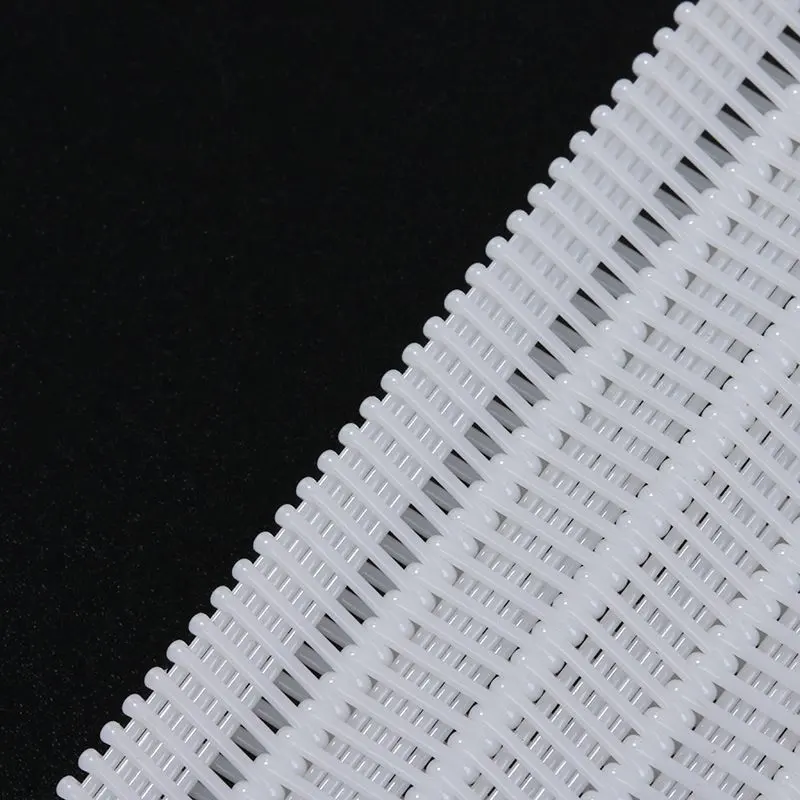

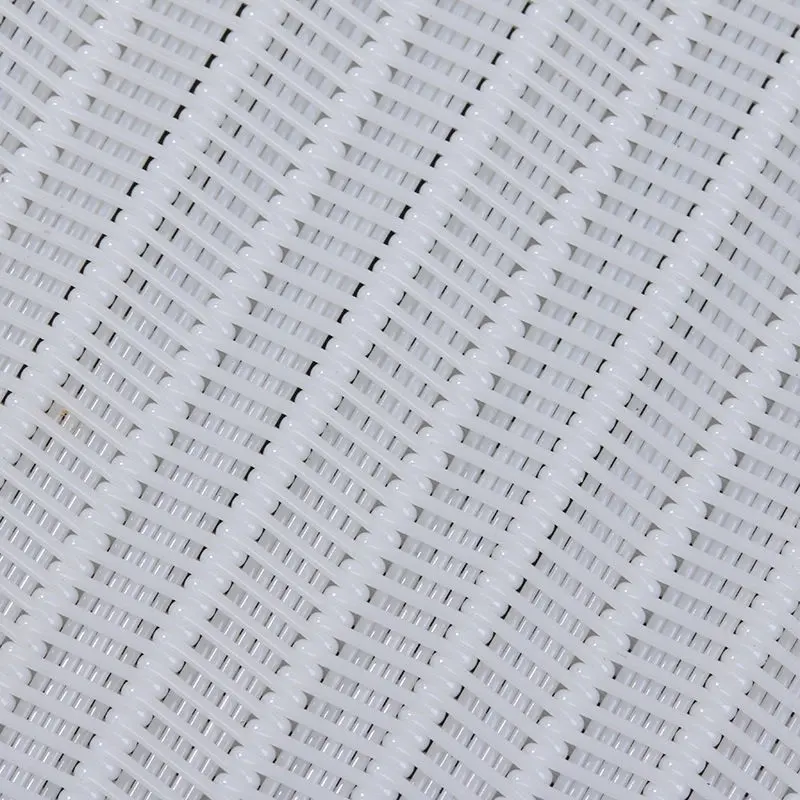

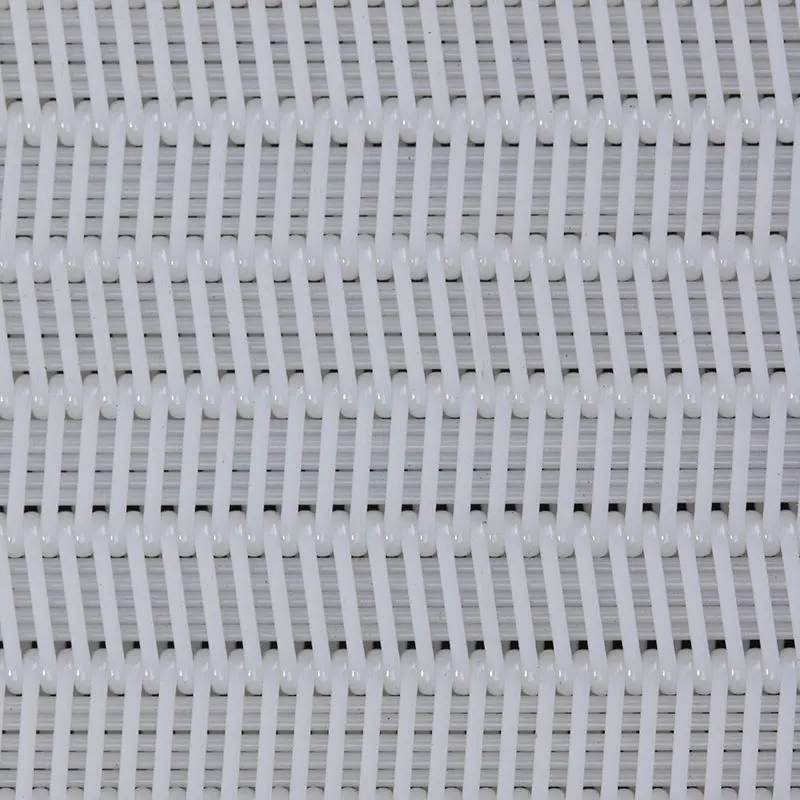

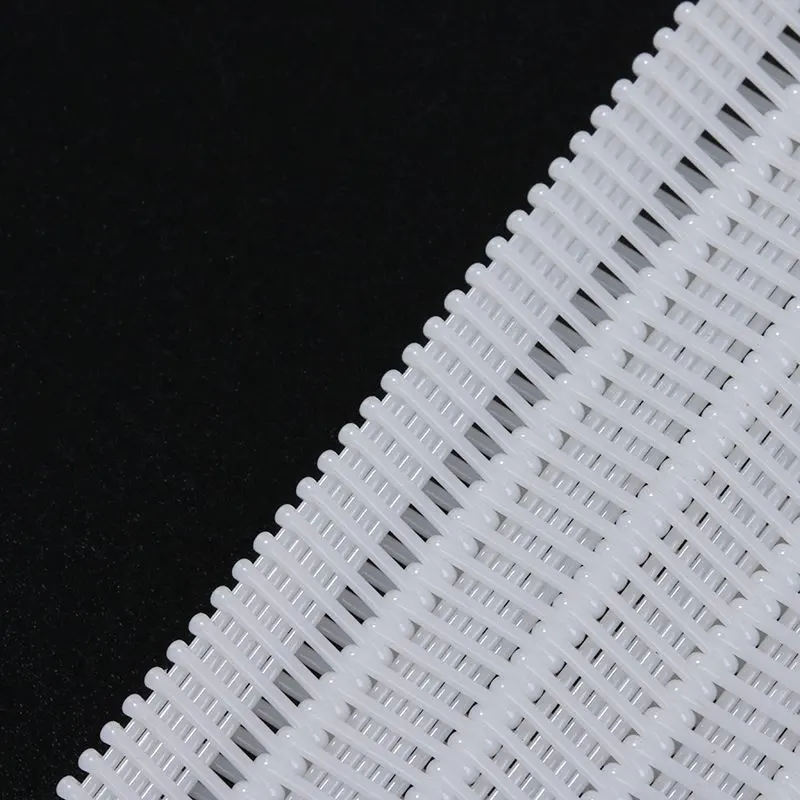

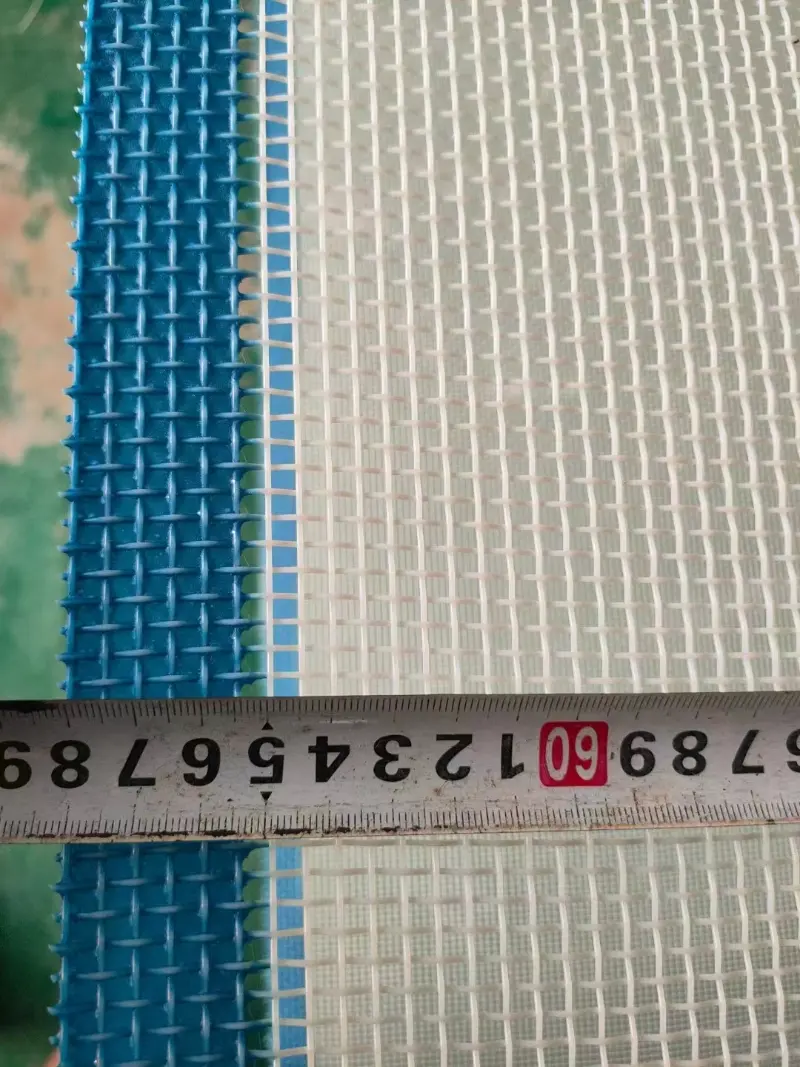

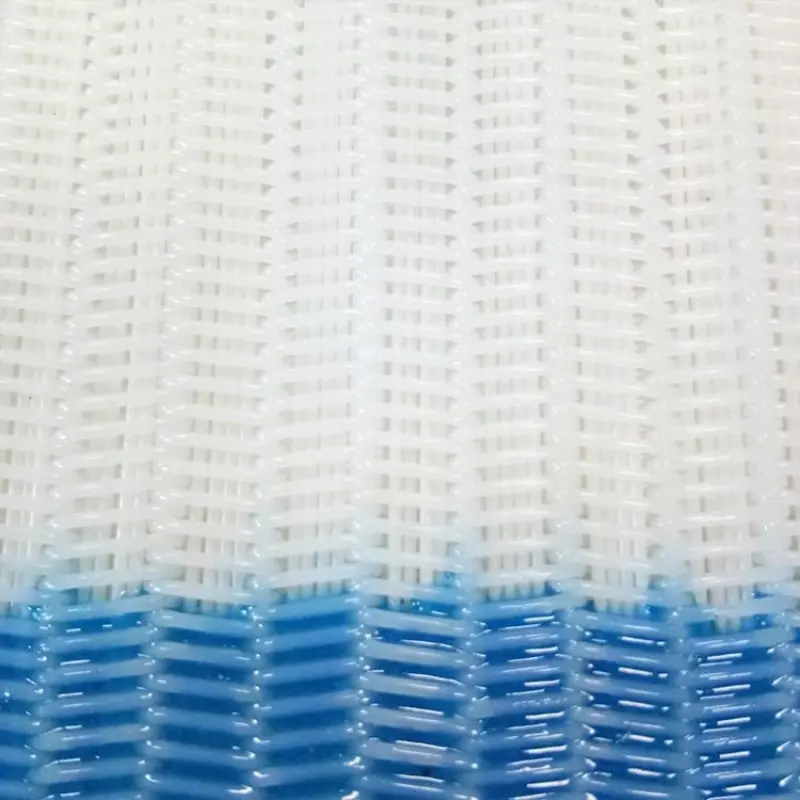

Balanced Spiral mesh features a simple yet effective design, constructed from alternating left and right hand spiral coils. These coils are held in place by interconnecting crimp rods which run through the width of the belt. The edges of the belt can be supplied either welded or with a knuckled selvedge.

Balanced Spiral gains its excellent tracking properties by employing an alternating pattern which prevents the belt from pulling to one side. Lateral movement within the belt is reduced by the use of specially crimped rods which hold each spiral coil in place.

Balanced Spiral is most commonly supplied as friction-drive belt; however certain meshes can be supplied as Positive-Drive, allowing sprockets to engage with the belts mesh. Alternatively, we can supply Balanced Spiral with chain edges for high load applications.

Cross-Flights and Side Plates are available for inclined applications or product separation requirements. Wire Belt Company also supplies Double Balanced Spiral belting, for applications with particularly high load and/or for products which require a narrower aperture than is possible with standard balanced spiral belts.

Quality cross rods with larger diameter than spiral wires for higher durability.

Temperature range: -50°C to 1100°C.

Quick and easy to install.

Simple maintenance by replacing the broken parts easily.

Resistant to acid, alkaline, chemical, abrasion and corrosion.

Complying with food safety standards such as FDA, GMP and others up your request.

Features

1. Resistant to wide range of acids and organic solvents

2. Safe for food processing applications

3. Exceptional strength and dimensional stability

4. Working temperature: +150°C to -75°C in dry conditions. 70°C+ in wet conditions

Application

Suitable for pulp-liquor separator,high-pressure press-filter washer,horizontal belt washer,netting belt coal-washer,pulp washing,coal washin,wine chaff dehydration,bran vinegar dehydration,sludge dehydration,chemical industry.

Polyester Spiral Press-Filter Fabrics are mainly used in paper making, printing and dyeing, food, pharmaceutical, ceramics and solid-liquid separation industries like sludge dehydration

1.Dewatering of inert sludge quarries or mines

2.Dewatering of biological or chemical sludger from municipality sewage plants.

3.Pressing of grapes,fruit and others

4.Foodstuffs processing.

Four selling pointsrest assured to use

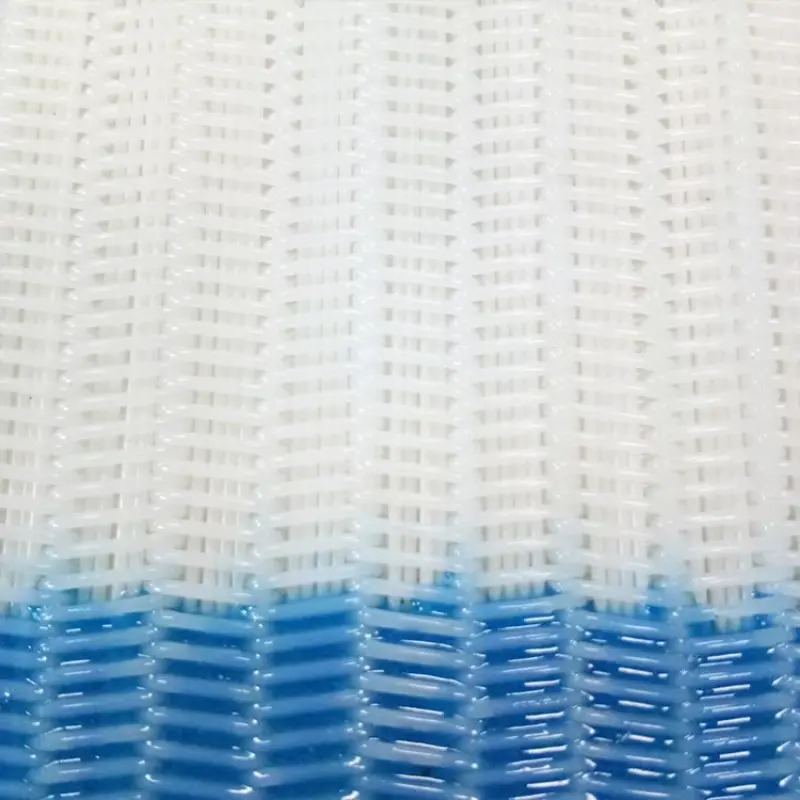

Pros and cons: The front is smooth, whichhelps the waterflow away quickly, Rough back,increased wearresistance withroller contact surface

Thread equalization technique: The net surface is flat, Resistance to tension

Far infrared hightemperature setting, Don’t run off

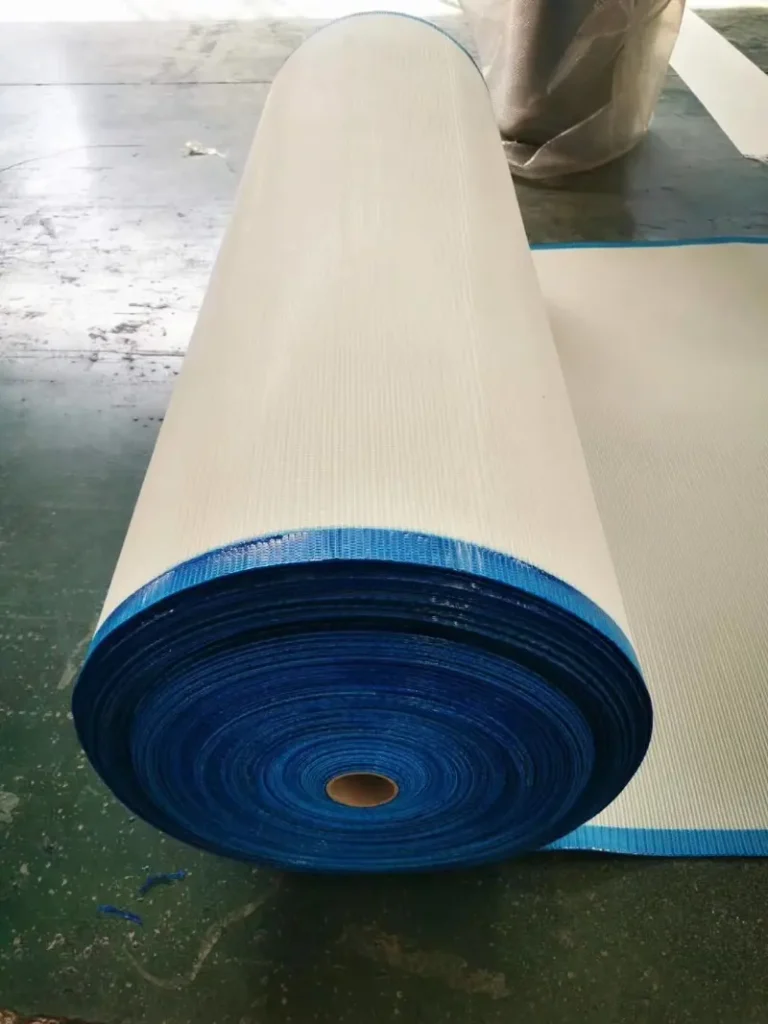

lmported AB rubber, edge sealing, Non rotten edgeLife for a long time

XURUI manufacturer high quality mesh belt for different industry application and machine, such as juice press, belt filter press, horizontal vacuum belt filter, food drying machine, paper machine, artificial board pavement machine, dryer paper machine, non-woven equipment, etc. Welcome to contact us to get suitable belt.

Goble Exhibition Show

Application area:

The main application industries of desulfurization fltercloth are gypsum desulfurization in power plants, lithiummica, potassium feldspar, petrochemicals, phosphoricacid, potassium salt, citric acid, chemical industry, aluminum industry, and various metallurgical benefciationindustries, as well as electroplating wastewater fltration.Its main characteristics are fast dehydration, easy un-loading, good cake stripping, strong wear resistance,and high stability.

Packaging and Transportation

Self provided logistics, strong production capacity, same day delivery for urgent orders

Related Products

Related Products