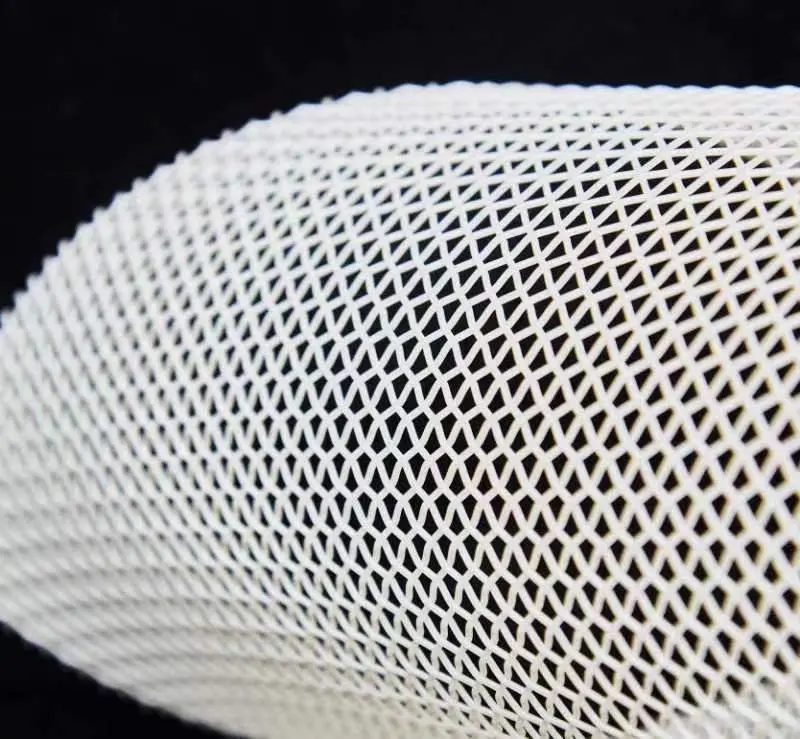

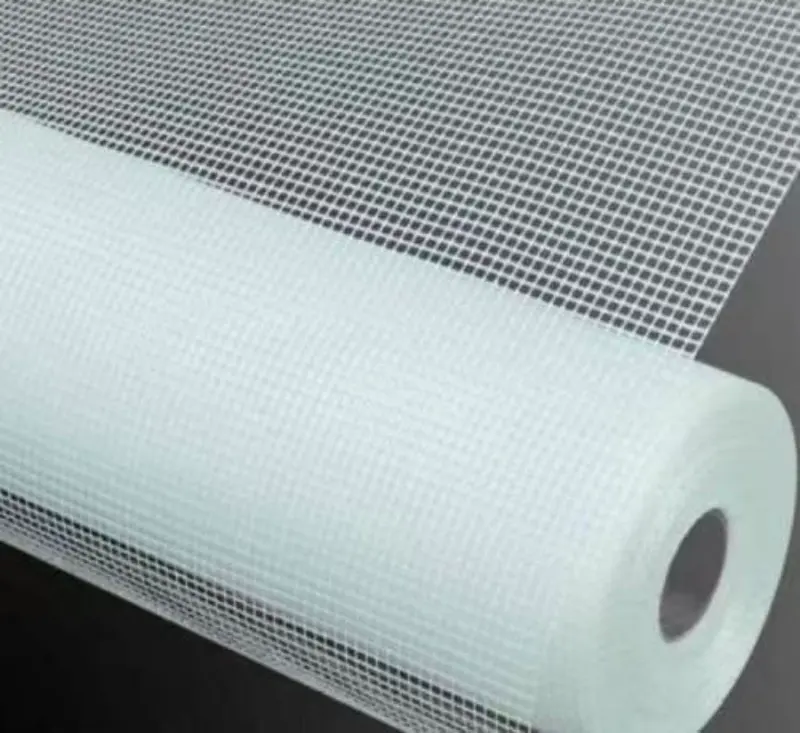

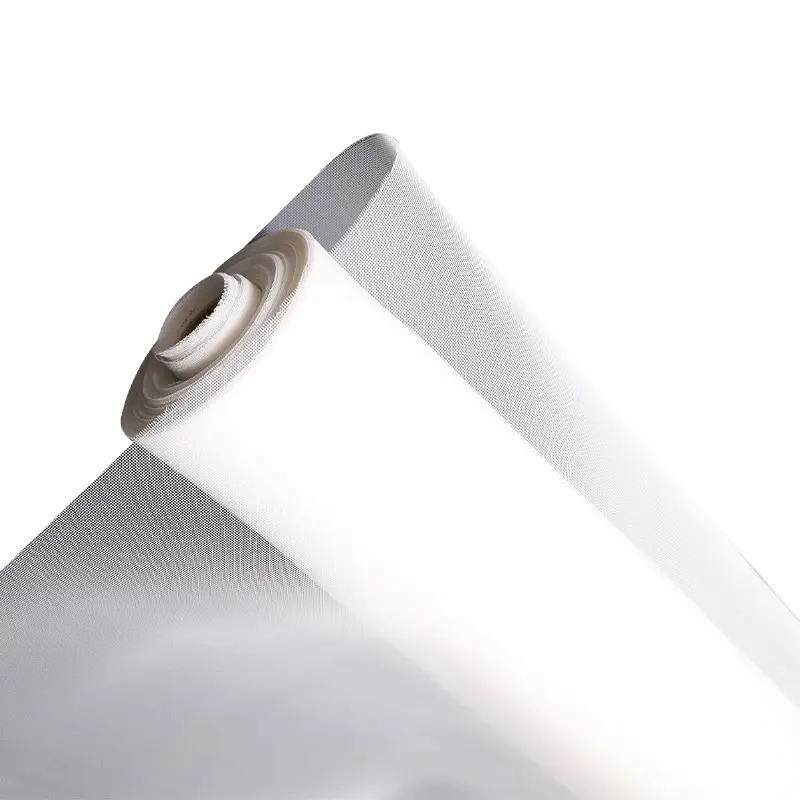

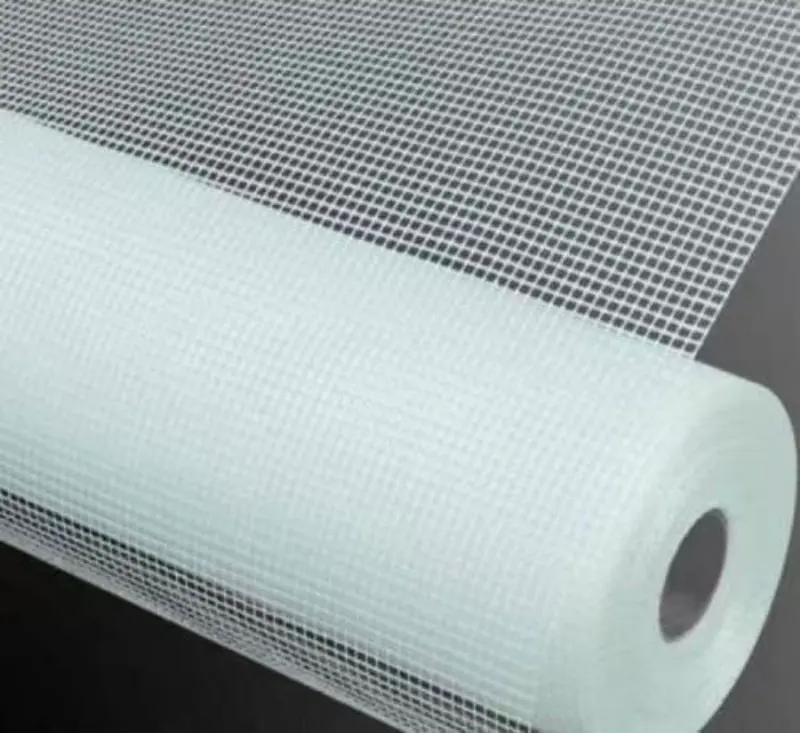

Filter Cloth for Press Filter Machine

Filter press cloth plays the role of filtering and separating solid-liquid mixtures in the filter press. Its quality and performance directly affect the working efficiency and filtering effect of the filter press. The filter cloth allows liquid to penetrate through tiny pores, while trapping solid particles on the surface of the filter cloth to form a filter cake. During the operation of the filter press, the filter cloth needs to withstand high pressure and have good water permeability and wear resistance to ensure a smooth filtering process.

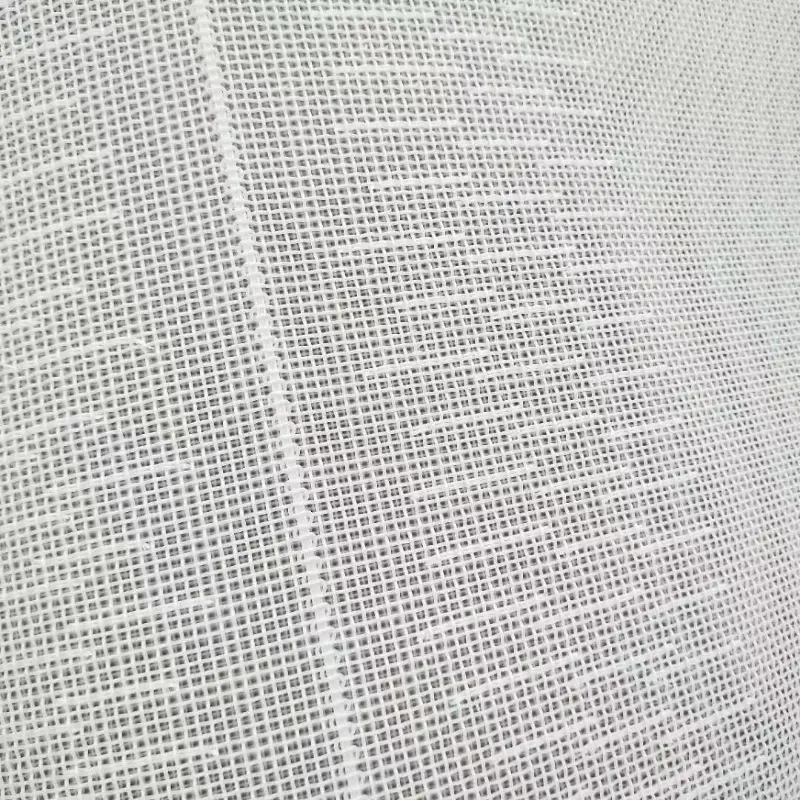

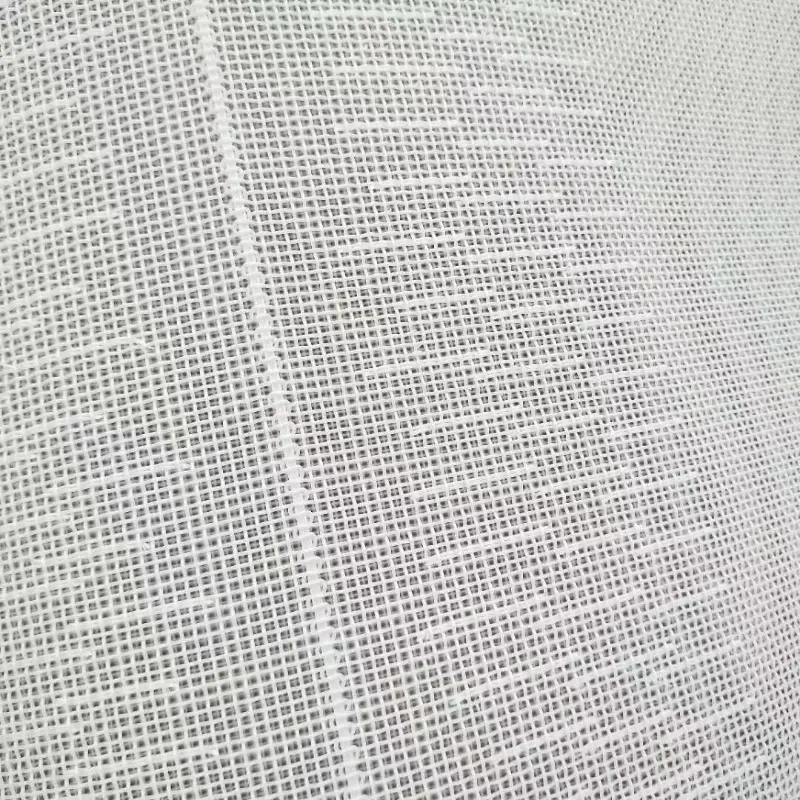

The equipment using polyester fabric will produce high friction electrostatic when it runs at a high speed. To dissipate this static electricity, conductive threads, normally bronze or stainless steel wires are woven through the polyester fabric. And this new fabric is generally called as anti-static filter fabric. Our range of anti-static filter fabric is widely used in various aspects including pulping drying, chemical fiber industry, high density board, sludge dehydration, conveyor belt, environmental protection, vacuum filtration, rubber and chemical industry, etc.When the equipments which are using polyester fabric are running in high speed, it can produce friction electrostatic. There is a conductive fiber through the polyester anti-static fabrics which can release the friction electrostatic, thus play a role in anti-static.

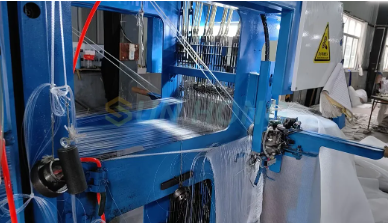

Production Process

1.Warping:use warping machine with automatic tension adjustment to make the tension of each warp within the allowable range, so as to ensure the uniformity of the horizontal air permeability of the screen and maintain the flatness and beauty of the screen.

2.Weaving machine:weaving with imported TEXO loom. This machine has the functions of servo feeding and active curling. The distance between each weft is equal to ensure the uniformity of the weft density when weaving the screen.

3.One-time setting: use the 7.5m hot air setting machine of SUN HONG to ensure that every square centimeter of the net surface is heated evenly during the setting process. The constant temperature hot air completely penetrates the screen, so that the warp and weft can be heated uniformly, so that the entire screen is soft and has a tough stiffness, and can also shrink and stretch the screen uniformly, thereby ensuring uniform air permeability of the entire screen.

4.Cutting:According to the customer’s different net specifications, cut into different lengths and widths.

5.Plug-in interface:We use imported spiral ring for the interface ring. The interface part of each screen is made by workers manually weaving each spiral ring, one by one.

6.Secondary setting:the inserted mesh curtain is heated and shaped again to make the mesh surface smoother, especially the interface part is guaranteed to be smooth without hooks.

7.Edge trimming and ironing:trim the edges of the net neatly and seal the wire with a soldering iron.

XURUI manufacturer high quality mesh belt for different industry application and machine, such as juice press, belt filter press, horizontal vacuum belt filter, food drying machine, paper machine, artificial board pavement machine, dryer paper machine, non-woven equipment, etc. Welcome to contact us to get suitable belt.

Application area:

Related Products

Related Products