Wie lässt sich die Schlammentwässerungseffizienz in modernen Abwasserbehandlungsanlagen mithilfe von Bandpressfiltertüchern verbessern?

Veröffentlichungsdatum: 12.09.2025

Die Schlammentwässerung ist ein entscheidender Schritt in der modernen Abwasserbehandlung. Angesichts immer strengerer Umweltauflagen und -vorschriften müssen Kläranlagen und Industrieanlagen dringend die Effizienz der Schlammentwässerung verbessern, um den Feststoffgehalt im Abwasser zu reduzieren und die Behandlungskosten zu senken. Der Einsatz von Bandpressfiltertüchern ist dabei besonders wichtig. Xurui untersucht, wie Bandpressfiltertücher die Effizienz der Schlammentwässerung steigern und der Abwasserbehandlungsindustrie zu einer effizienteren Schlammbehandlung verhelfen können.

Funktionsprinzip des Bandpressen-Filtertuchs

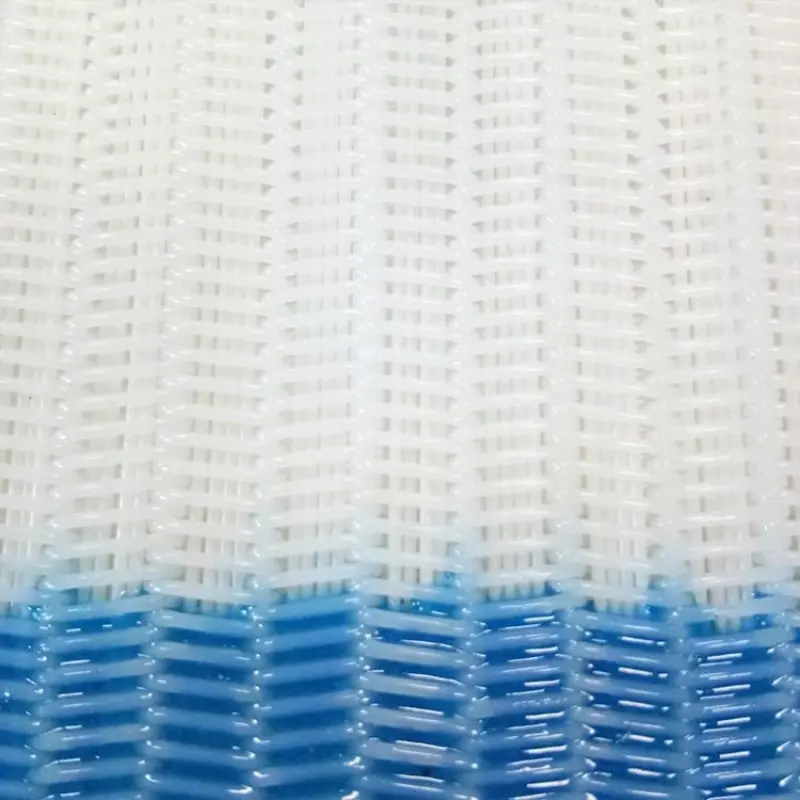

Bandfiltertücher sind Hochleistungsfiltertücher für Entwässerungsprozesse und finden breite Anwendung in der Abwasserbehandlung sowie in der chemischen, Lebensmittel- und pharmazeutischen Industrie. Ihre Hauptfunktion besteht in der Filtration in Bandfilterpressen. Durch Hochdruckwasser- oder Luftstrom wird dem Schlamm Wasser entzogen, wodurch das Schlammvolumen reduziert und bessere Ergebnisse bei der Schlammbehandlung erzielt werden.

Die Filtertücher für Bandfilterpressen bestehen typischerweise aus mehreren Lagen unterschiedlicher Materialien und zeichnen sich durch hohe Festigkeit, Verschleißfestigkeit und ausgezeichnete Durchlässigkeit aus. Die Beschaffenheit des Filtertuchs beeinflusst die Entwässerungseffizienz maßgeblich; verschiedene Materialien, Faserstrukturen und Porositäten bestimmen den Entwässerungseffekt des Klärschlamms.

Wie man die Schlammentwässerungseffizienz mit Bandfilterpressen-Filtertüchern verbessern kann

Optimierung der Filtrationsleistung

Die Filtertücher von Bandfilterpressen ermöglichen eine präzise Auswahl der Porengröße und gewährleisten so eine effiziente Trennung von Wasser und Feststoffen. Hochwertige Filtertücher für die Abwasserbehandlung Sie bieten eine höhere Filtrationsgenauigkeit und verhindern effektiv das Durchdringen von Schlammpartikeln, wodurch die Entwässerungseffizienz verbessert wird. Die Wahl geeigneter Filtertuchmaterialien und -porosität gewährleistet, dass sich der Schlamm während der Entwässerung nicht verklemmt und somit die Schlammbehandlungskapazität erhöht wird.

Haltbarkeit verbessern und Lebensdauer verlängern

Hochverschleiß- und korrosionsbeständige Filtertücher für Bandfilterpressen gewährleisten eine gleichbleibende Leistung über lange Zeit. Bei der Abwasserbehandlung kommt das Filtertuch häufig mit Schlamm in Kontakt; ist es von minderer Qualität, neigt es zu vorzeitigem Verschleiß oder Beschädigung, was die Entwässerungseffizienz beeinträchtigt. Hochwertige Filtertücher verlängern die Lebensdauer, reduzieren die Austauschhäufigkeit und die Wartungskosten und gewährleisten eine kontinuierliche Entwässerungseffizienz in Kläranlagen.

Reduzierter Energieverbrauch

Das optimierte Design und die hocheffiziente Filtrationsfunktion der Bandfilterpresstücher erleichtern den Entwässerungsprozess. Das Filtertuch minimiert den Feuchtigkeitsgehalt im Klärschlamm, wodurch Mehrfachfiltrationen vermieden und der Energieverbrauch gesenkt werden. Durch die Auswahl geeigneter Bandfilterpresstücher können Kläranlagen nicht nur die Entwässerungseffizienz verbessern, sondern auch den Energieverbrauch reduzieren und so die Ziele des Umweltschutzes und der Energieeinsparung erreichen.

Verbesserte Schlammtextur nach der Entwässerung

Die Qualität der Filtertücher in Bandfilterpressen bestimmt maßgeblich die Konsistenz des entwässerten Klärschlamms. Hochwertige Filtertücher entfernen das Wasser vollständig aus dem Klärschlamm, was zu einem geringeren Restfeuchtegehalt nach der Entwässerung führt. Entwässerter Klärschlamm lässt sich leichter entsorgen oder verwerten, beispielsweise durch Deponierung oder Verbrennung, und trägt so zur Klärschlammbehandlung und Wertstoffrückgewinnung bei.

Wie wählt man das richtige Bandfilterpressentuch aus?

Bei der Auswahl von Filtertüchern für Bandfilterpressen müssen Kläranlagen die spezifische Schlammart, die Entwässerungsanforderungen und die Betriebsbedingungen der Anlage berücksichtigen. Im Folgenden sind einige wichtige Faktoren aufgeführt, die bei der Auswahl von Filtertüchern für Bandfilterpressen zu beachten sind:

Material und Haltbarkeit: Gängige Filtergewebematerialien sind Polyester, Polypropylen und Nylon. Unterschiedliche Materialien weisen unterschiedliche Temperatur-, Säure- und Laugenbeständigkeit sowie Korrosionsbeständigkeit auf. Die Auswahl des geeigneten Filtergewebematerials basierend auf den chemischen Eigenschaften des Abwassers kann die Entwässerungseffizienz verbessern und die Lebensdauer verlängern.

Porosität und Webverfahren: Die Porosität und Webart des Filtertuchs von Bandfilterpressen beeinflussen direkt die Filtrationseffizienz und die Schlammentwässerung. Eine geringere Porosität verbessert zwar die Entwässerungsgenauigkeit, kann aber zu einer geringeren Durchflussrate führen; daher muss ein Gleichgewicht zwischen Effizienz und Durchflussrate gefunden werden.

Anpassungsfähigkeit und Wartungsanforderungen: Mit dem kontinuierlichen Fortschritt moderner Abwasserbehandlungstechnologien hat sich auch die Anpassungsfähigkeit von Bandfilterpressen-Filtertüchern verbessert. Hochleistungs-Bandfilterpresstücher Sie können sich an höhere Betriebsdrücke und komplexere Schlammarten anpassen, und auch ihre Reinigung und Wartung sind einfacher geworden.

Abschluss

Zusammenfassend lässt sich sagen, dass die Bedeutung von Bandfilterpresstüchern in der modernen Abwasserbehandlung nicht zu unterschätzen ist. Durch die Auswahl geeigneter Filtertücher können Kläranlagen die Schlammentwässerungseffizienz deutlich verbessern, die Behandlungskosten senken und zu einem umweltfreundlicheren und energieeffizienteren Betrieb beitragen. Da die Abwasserbehandlungsbranche weiterhin höhere Effizienz und Nachhaltigkeit fordert, wird sich die Technologie der Bandfilterpresstücher stetig weiterentwickeln und der Branche neue Innovationen und bahnbrechende Entwicklungen bescheren.

Wenn Sie nach Lösungen zur Verbesserung der Schlammentwässerungseffizienz suchen, wählen Sie hochwertiges Bandfilterpressentuch ist zweifellos eine lohnenswerte langfristige Anlagestrategie.