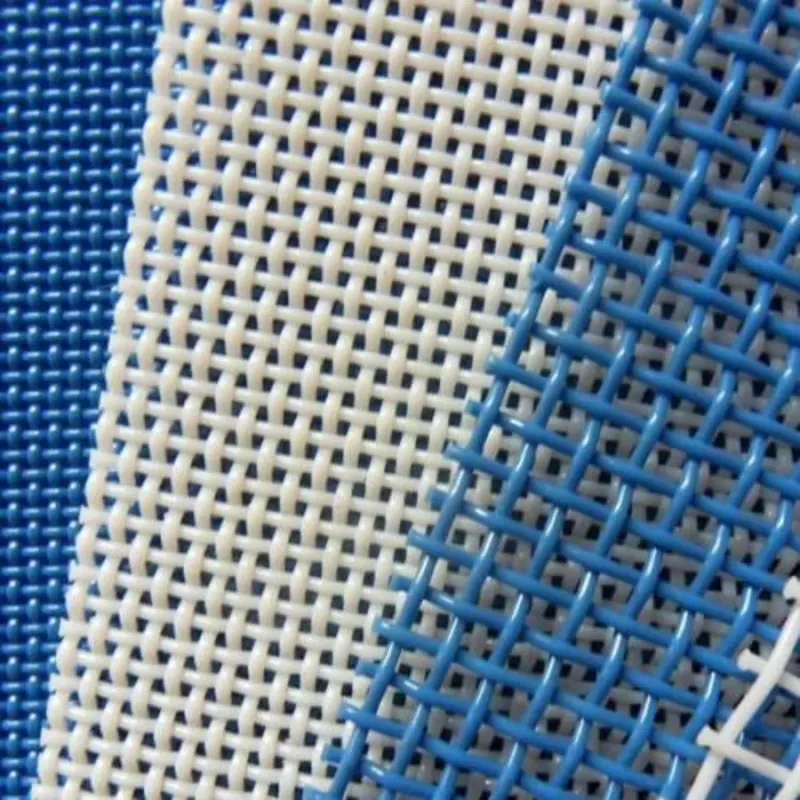

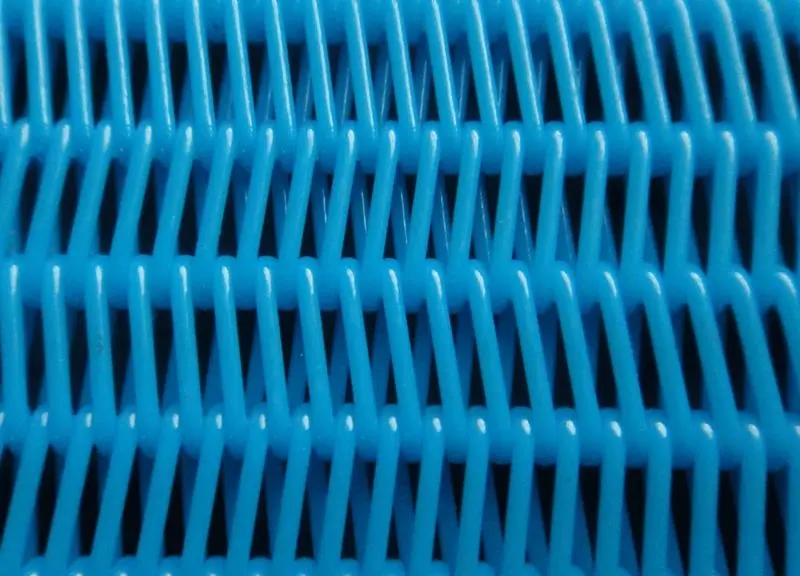

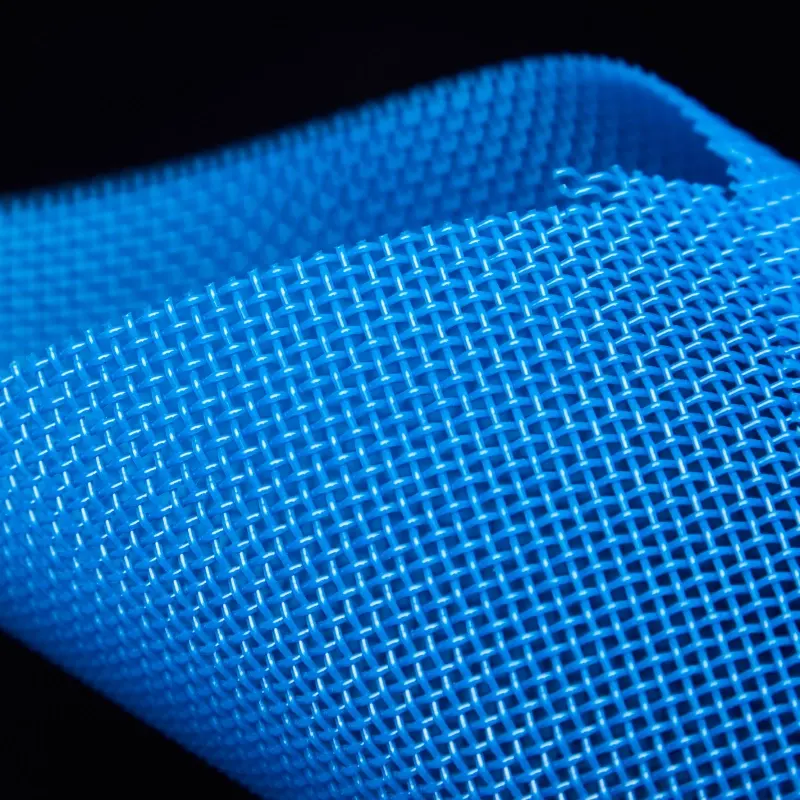

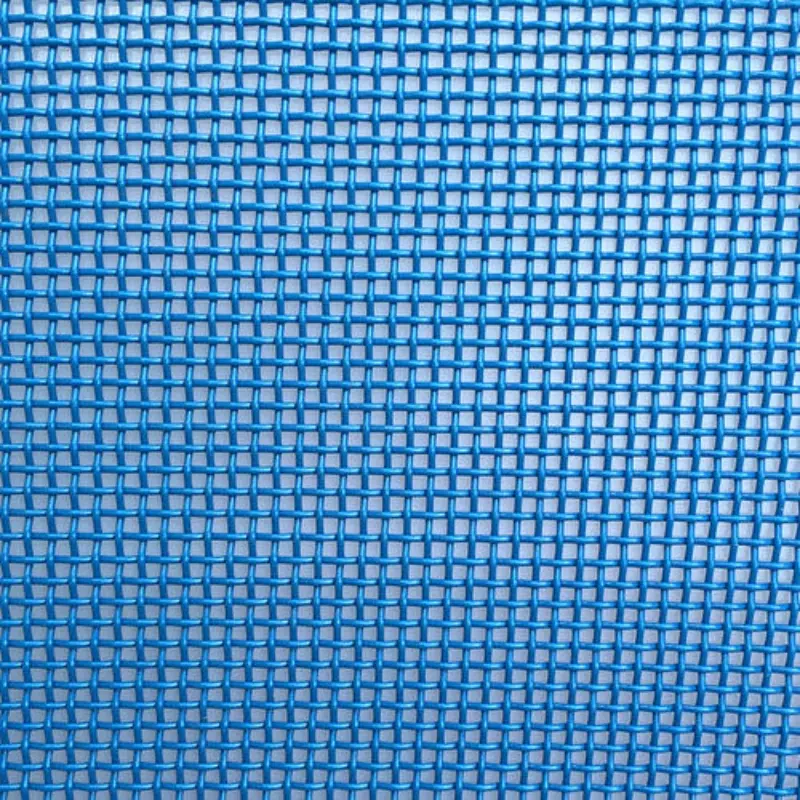

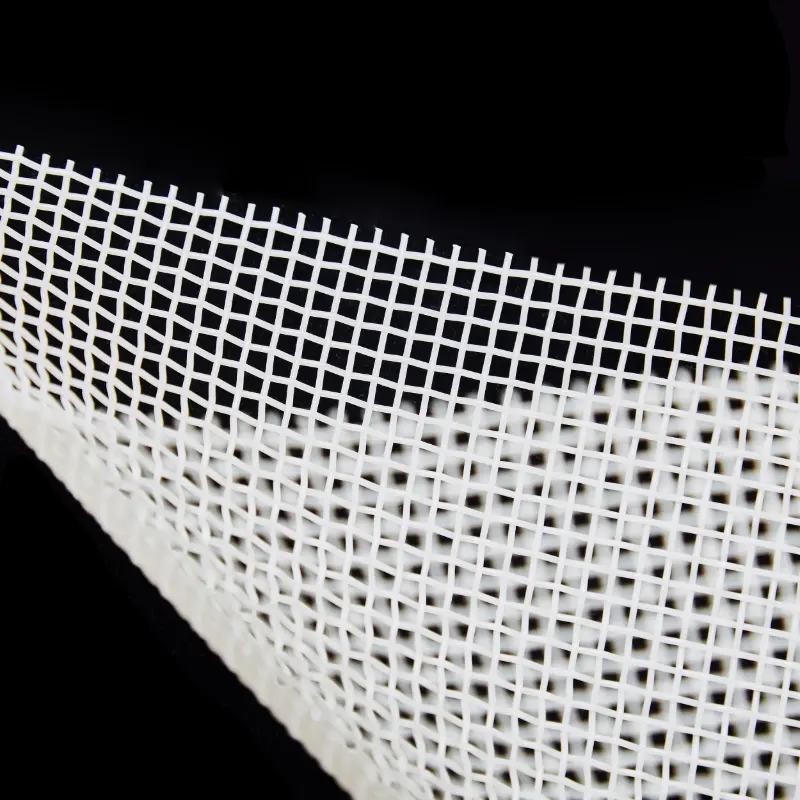

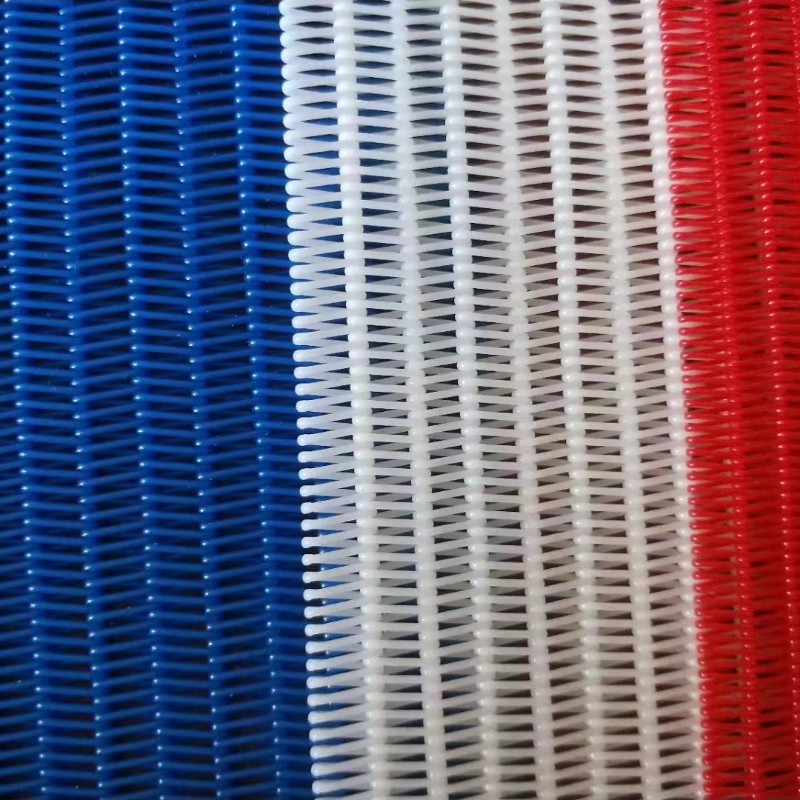

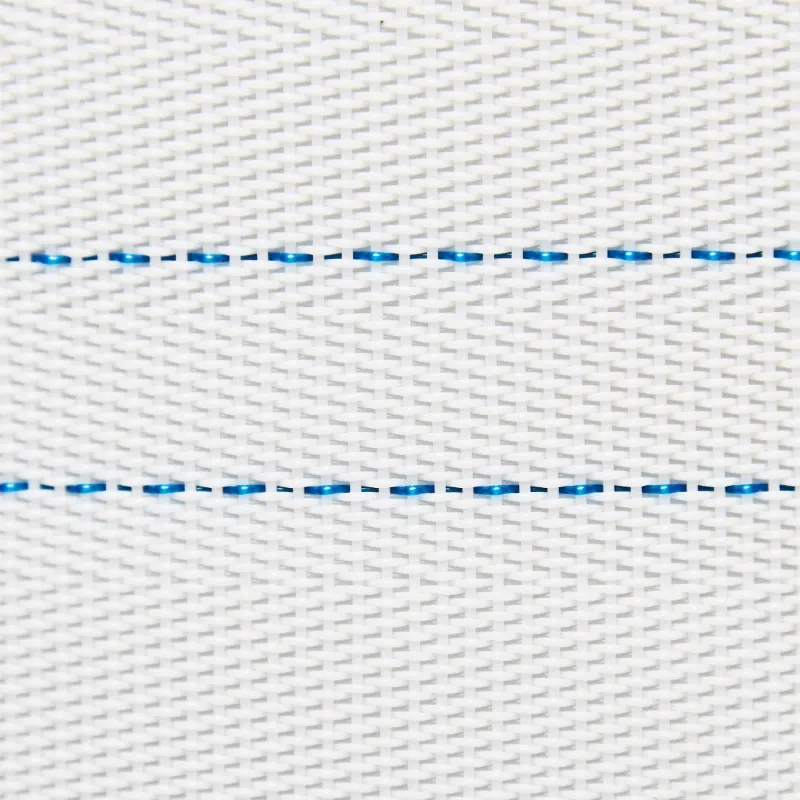

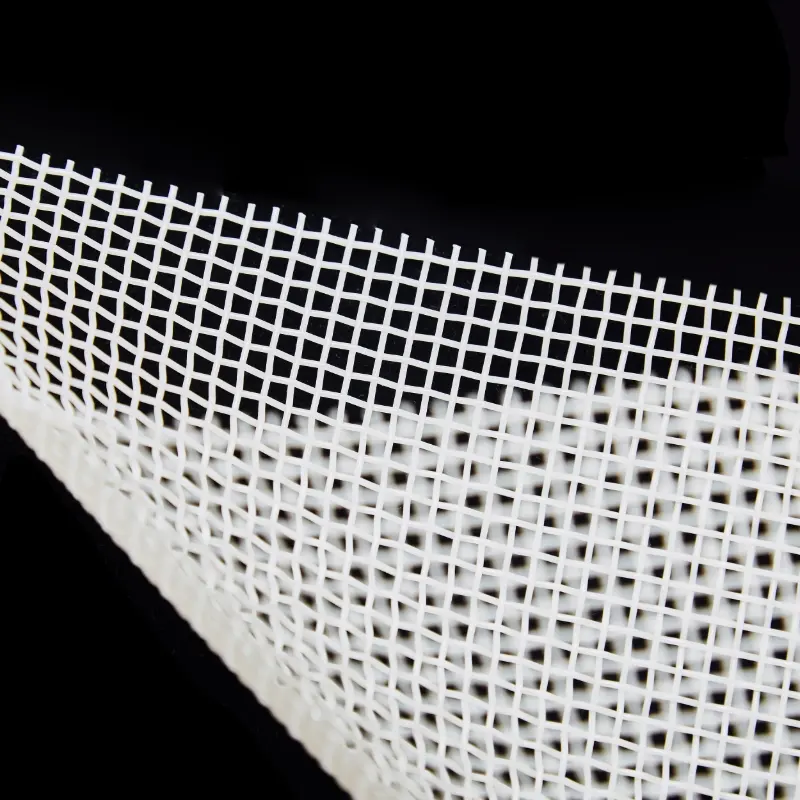

Polyester spiral press-filter fabrics are adding the filler wire into spiral ring, so the air permeability is reduced and less material loss on the surface of the fabric. They are mainly used in paper making, printing and dyeing, food, pharmaceutical, ceramics and solid-liquid separation industries like sludge dehydration.

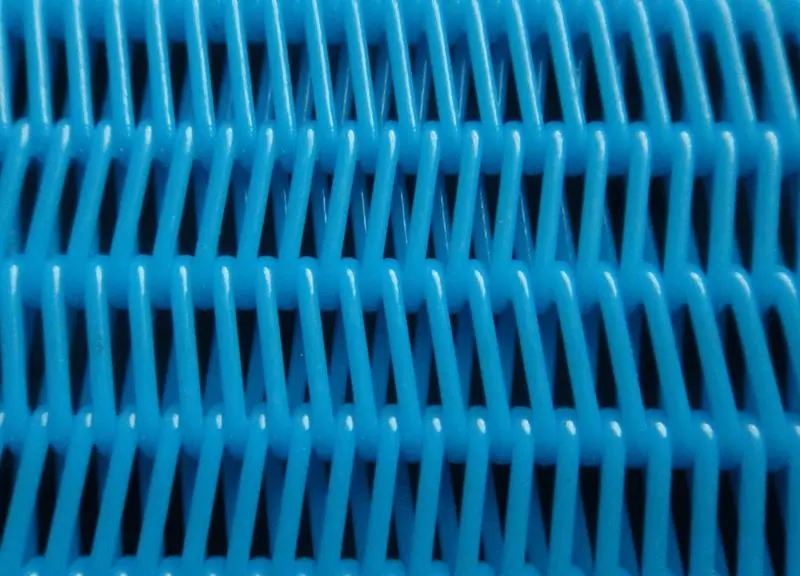

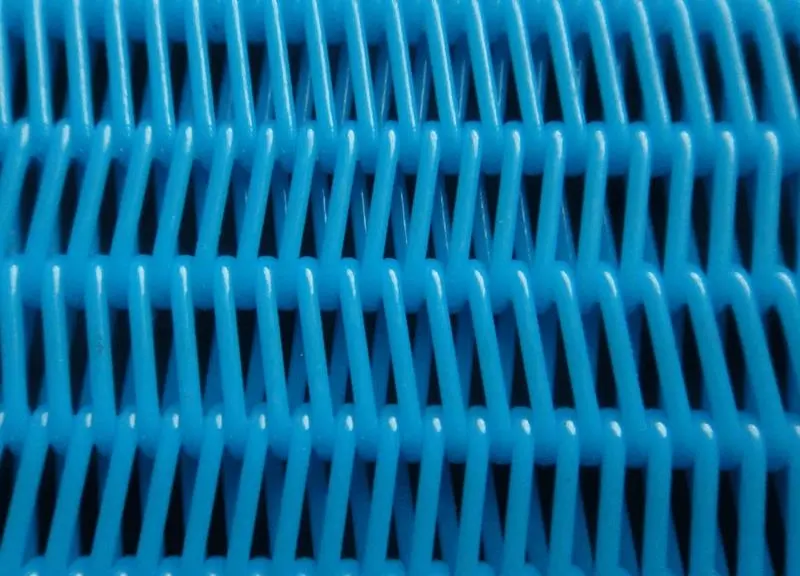

Polyester Spiral Mesh Belts Properties:

♦ Use hot air to set the shape, evenly heat, and improve the service life of the mesh belt.

♦ Excellent chemical stability, BPA-free, Food grade certification

♦ Sealed edges for lasting, economical solutions

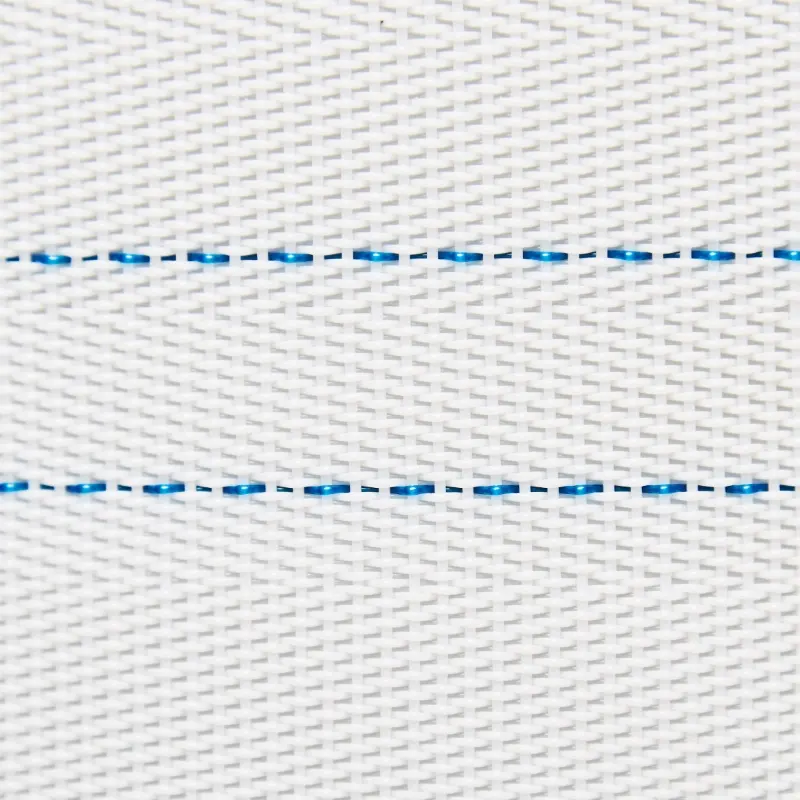

♦ Seamless connection, no swelling at the joint, and the same air permeability in the whole filtering area.

♦ Selected raw yarn, smooth surface, not easy to stick, easy to clean.

Production Process

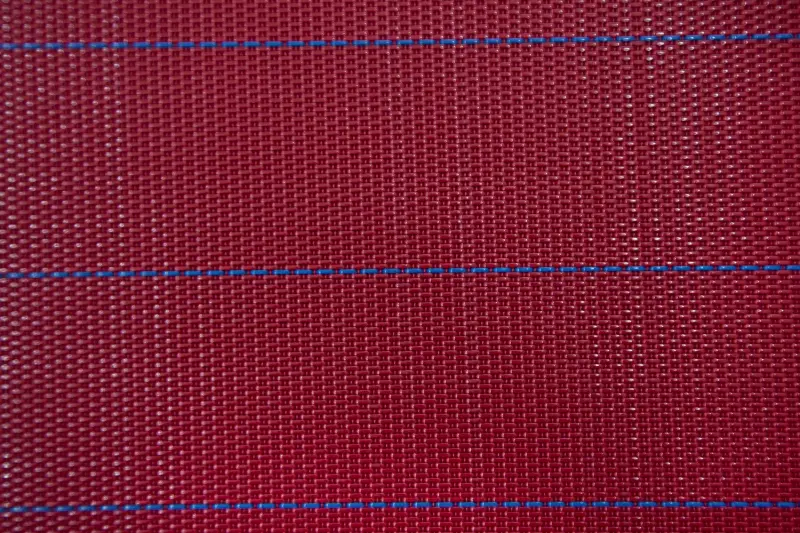

1.Warping:use warping machine with automatic tension adjustment to make the tension of each warp within the allowable range, so as to ensure the uniformity of the horizontal air permeability of the screen and maintain the flatness and beauty of the screen.

2.Weaving machine:weaving with imported TEXO loom. This machine has the functions of servo feeding and active curling. The distance between each weft is equal to ensure the uniformity of the weft density when weaving the screen.

3.One-time setting: use the 7.5m hot air setting machine of SUN HONG to ensure that every square centimeter of the net surface is heated evenly during the setting process. The constant temperature hot air completely penetrates the screen, so that the warp and weft can be heated uniformly, so that the entire screen is soft and has a tough stiffness, and can also shrink and stretch the screen uniformly, thereby ensuring uniform air permeability of the entire screen.

4.Cutting:According to the customer’s different net specifications, cut into different lengths and widths.

Products Application

Polyester spiral press-filter fabrics are adding the filler wire into spiral ring, so the air permeability is reduced and less material loss on the surface of the fabric. They are mainly used in paper making, printing and dyeing, food, pharmaceutical, ceramics and solid-liquid separation industries like sludge dehydration.

| Raw material imported from Germany | ·13 production QC processes line |

| ·200% longer life | ·35000$ annual cost savings |

| ·15-year experienced workers | ·28 years of R&D and production experience |

| ·All kinds of interface | ·Imported alloy threading |

Application

Suitable for pulp-liquor separator,high-pressure press-filter washer,horizontal belt washer,netting belt coal-washer,pulp washing,coal washin,wine chaff dehydration,bran vinegar dehydration,sludge dehydration,chemical industry.

Polyester Spiral Press-Filter Fabrics are mainly used in paper making, printing and dyeing, food, pharmaceutical, ceramics and solid-liquid separation industries like sludge dehydration

1.Dewatering of inert sludge quarries or mines

2.Dewatering of biological or chemical sludger from municipality sewage plants.

3.Pressing of grapes,fruit and others

4.Foodstuffs processing.

Four selling pointsrest assured to use

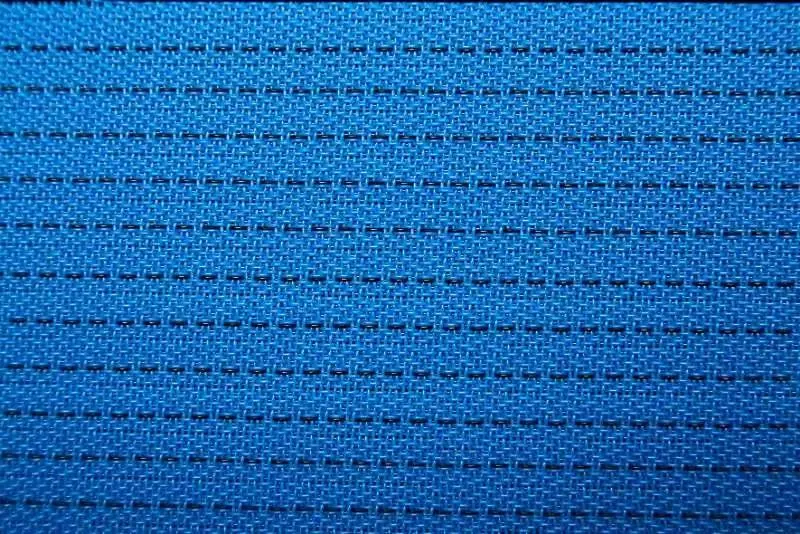

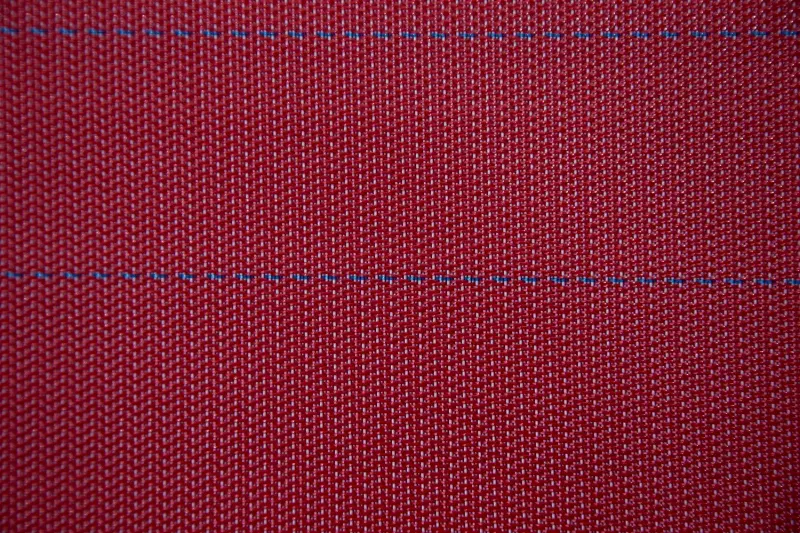

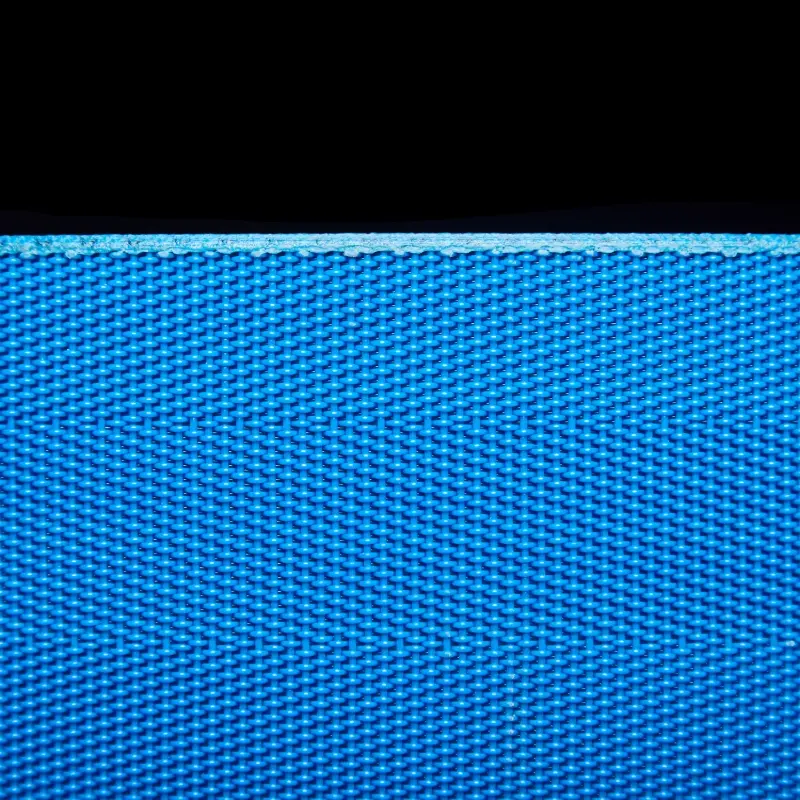

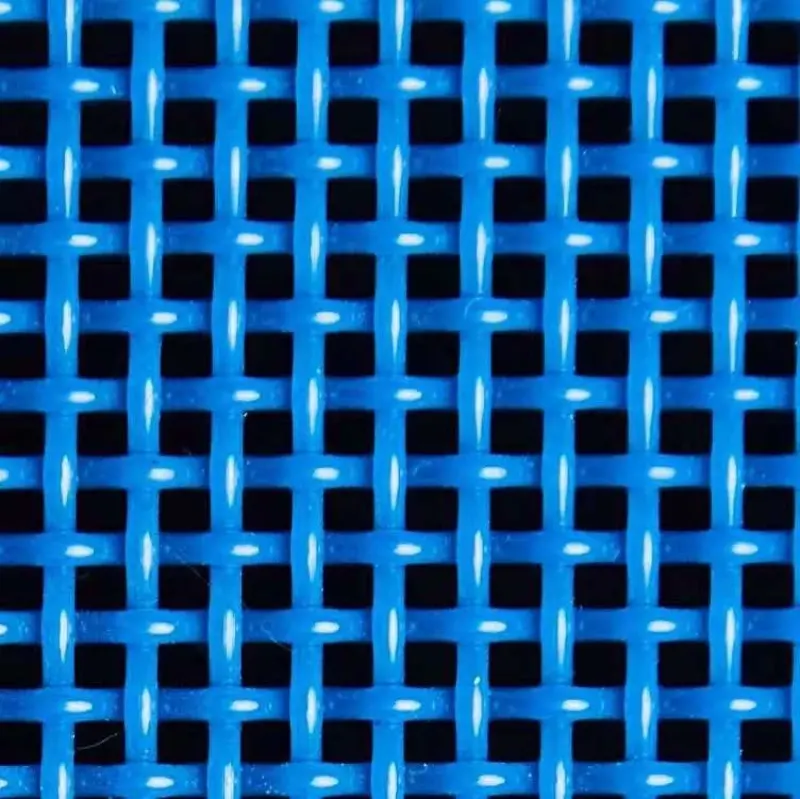

Pros and cons: The front is smooth, whichhelps the waterflow away quickly, Rough back,increased wearresistance withroller contact surface

Thread equalization technique: The net surface is flat, Resistance to tension

Far infrared hightemperature setting, Don’t run off

lmported AB rubber, edge sealing, Non rotten edgeLife for a long time

XURUI manufacturer high quality mesh belt for different industry application and machine, such as juice press, belt filter press, horizontal vacuum belt filter, food drying machine, paper machine, artificial board pavement machine, dryer paper machine, non-woven equipment, etc. Welcome to contact us to get suitable belt.

Goble Exhibition Show

Application area:

The main application industries of desulfurization fltercloth are gypsum desulfurization in power plants, lithiummica, potassium feldspar, petrochemicals, phosphoricacid, potassium salt, citric acid, chemical industry, aluminum industry, and various metallurgical benefciationindustries, as well as electroplating wastewater fltration.Its main characteristics are fast dehydration, easy un-loading, good cake stripping, strong wear resistance,and high stability.

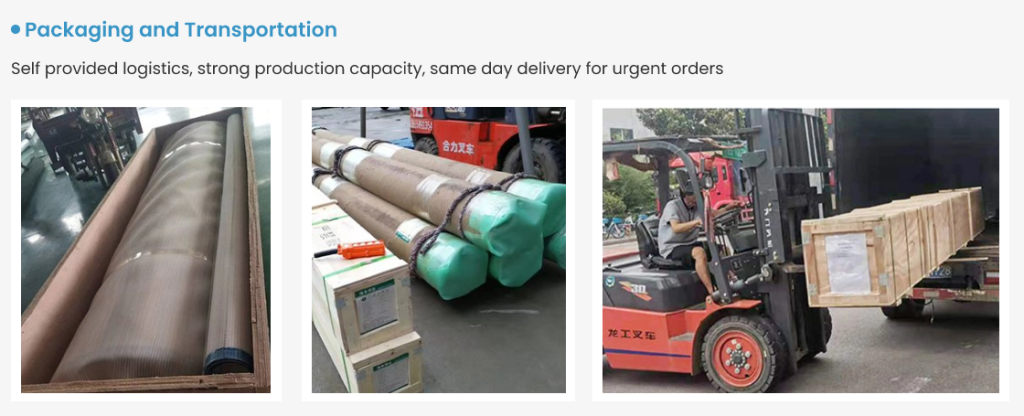

Packaging and Transportation

Self provided logistics, strong production capacity, same day delivery for urgent orders

1. Can I have a sample order ?

A: Yes, we are welcome sample order to test and check quality. Mixed samples are acceptable.

2. What about the lead time ?

A: Sample needs about 3 days, mass production time needs about one week for order quantity more than.

3. What is your MOQ?

A: 100, 1pc for sample checking is available.

4. How do you ship the goods and how long does it take to arrive ?

A: Express and ocean ship, the express usually are DHL,UPS, FedEx or TNT. It usually takes 3-5

days to arrive. Airline also optional.

5. Is it OK to print my logo

A: Yes. Pleas inform us formally before our production and confirm the desige firstly

based on our sample.

Related Products

Related Products