Improving Gypsum Dewatering Efficiency with High-Performance Vacuum Belt Filter Cloth

Release time: 2025-12-10

Table of Contents

In the flue gas desulfurization (FGD) systems of power plants and chemical facilities, the final stage—gypsum dewatering—is critical for operational compliance and byproduct quality. The efficiency of this process relies heavily on the quality of the filtration media. Specifically, using high-performance vacuum belt filter cloth is the most effective way to ensure low cake moisture and high throughput.

As a leading vacuum belt filter cloth manufacturer, we understand that selecting the right fabric is not just about filtration; it is about optimizing the entire lifecycle of your FGD system.

The Role of Vacuum Belt Filter Cloth in Gypsum Dewatering

The primary goal of gypsum dewatering is to reduce the water content in the gypsum slurry to below 10%. A high-quality filter cloth acts as the interface between the vacuum pump and the slurry. If the cloth has poor permeability or is prone to “blinding” (clogging), the vacuum pressure cannot effectively pull moisture through the cake.

By choosing high-performance vacuum belt filter cloth, operators can achieve:

Lower Residual Moisture: Improved pore structures allow for better air-to-liquid ratios.

Faster Cake Discharge: Superior surface smoothness ensures the gypsum cake peels off easily, reducing downtime for cleaning.

Increased Tensile Strength: Vacuum belts are under constant tension; high-strength polyester or polypropylene fabrics prevent stretching and tracking issues.

Solving Common Challenges with Professional Filtration Media

Many plants struggle with the premature wear of filter fabrics due to the abrasive nature of gypsum crystals and the acidic environment of the slurry. This is where the expertise of a specialized vacuum belt filter cloth manufacturer becomes invaluable.

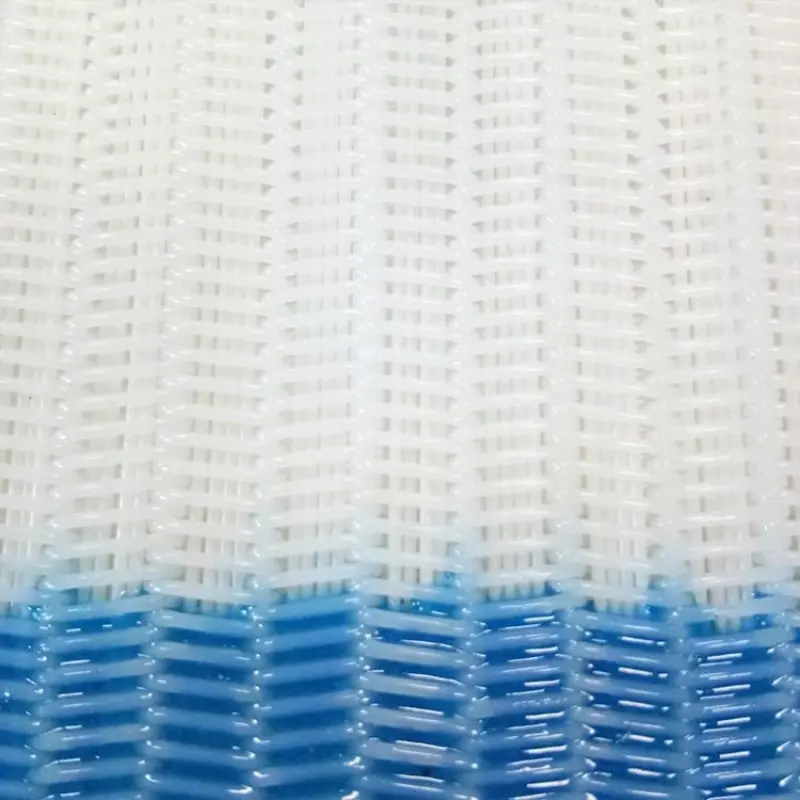

Standard fabrics may offer a lower upfront cost, but they often lead to frequent replacements. In contrast, premium desulfurization filter cloths are treated with heat-setting and calendering processes. This stabilizes the fabric dimensions and smooths the fibers to prevent fine particles from becoming trapped within the weave.

[Image showing a microscopic view of a calendered filter cloth weave versus a standard weave]

Key Features to Look For

When searching for the ideal solution for your facility, consider these technical specifications:

Acid and Alkali Resistance: Essential for enduring the chemical wash cycles in FGD systems.

Optimal Air Permeability: Balanced to maintain vacuum levels while ensuring fine particle retention.

Clipper Seam Durability: The joint is often the weakest point; high-performance belts use reinforced stainless steel or hidden seams for maximum longevity.

Comparison of Standard vs. High-Performance Filter Cloths

| Feature | Standard Filter Cloth | High-Performance Vacuum Belt Cloth |

| Service Life | 3 – 5 Months | 8 – 12+ Months |

| Cake Moisture Content | 12% – 15% | < 10% |

| Blinding Resistance | Moderate | High (with specialized coating) |

| Maintenance Frequency | High | Low |

Conclusion: Why Quality Matters

Investing in high-performance vacuum belt filter cloth is a strategic decision that pays for itself through reduced energy consumption and lower labor costs. As environmental regulations become stricter, maintaining an efficient dewatering process is no longer optional—it is a necessity for sustainable industrial operations.

If you are looking for a reliable vacuum belt filter cloth manufacturer to upgrade your FGD system, look for partners who offer technical support and customized weaving patterns tailored to your specific slurry density and particle size.