Key Factors to Consider When Purchasing Vacuum Filter Cloth for FGD Systems

Release time: 2025-12-26

Table of Contents

In the demanding environment of Flue Gas Desulfurization (FGD), the efficiency of your gypsum dewatering process hinges on a single component: the filter fabric. Selecting the right media is a complex decision that impacts both the purity of your gypsum byproduct and the operational lifespan of your machinery.

Whether you are upgrading an existing power plant or designing a new emission control system, understanding the technical requirements of corrosion-resistant vacuum desulfurization filter cloth is essential for long-term success.

Material Composition and Chemical Resistance

The slurry in an FGD system is often chemically aggressive, containing high concentrations of chlorides and varying pH levels. To prevent premature degradation, you must prioritize corrosion-resistant vacuum desulfurization filter cloth.

Typically, high-grade polyester (PET) or polypropylene (PP) are the preferred materials. Polyester offers excellent tensile strength and heat resistance, while polypropylene provides superior acid and alkali resistance. Choosing a material that matches your specific chemical profile ensures the cloth won’t lose structural integrity during intensive wash cycles.

Air Permeability and Filtration Precision

The balance between “letting liquid through” and “keeping solids back” is determined by permeability. For systems handling heavy slurry loads, using high-permeability vacuum belt filter cloth is vital.

If the permeability is too low, the vacuum pump must work harder, increasing energy costs and potentially leading to high cake moisture. Conversely, if it is too high, fine gypsum particles may pass through the mesh (turbidity), contaminating the filtrate. A professional manufacturer will help you calibrate the CFM (Cubic Feet per Minute) rating to match your vacuum pump’s capacity and the particle size of your gypsum.

Mechanical Durability and Wear Resistance

Vacuum belt filters operate under significant mechanical tension and constant friction against the vacuum box. Therefore, investing in wear-resistant vacuum belt filter cloth is a prerequisite for reducing downtime.

Key durability features to look for include:

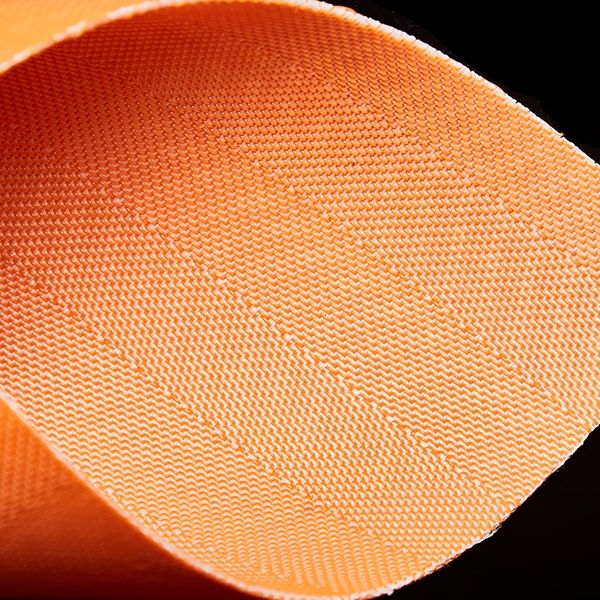

Monofilament vs. Multifilament: Monofilament fabrics are easier to clean and highly resistant to blinding, making them ideal for the abrasive nature of gypsum crystals.

Heat-Setting Treatment: This process ensures the belt remains dimensionally stable and does not stretch or shrink under operational heat.

Reinforced Edges: To prevent fraying and tracking issues, the edges should be coated or reinforced with high-strength resins.

Summary Checklist for Purchasing

| Selection Factor | Requirement for FGD Systems |

| Material | Acid/Alkali resistant (PP or Stabilized PET) |

| Fabric Type | Monofilament for better cake release |

| Seam Type | Stainless steel clipper seam with resin protection |

| Permeability | Optimized for specific vacuum capacity |

| Surface Finish | Calendered for smooth cake discharge |

The Importance of Seam Integrity

The seam is the most frequent point of failure in any industrial belt. For FGD applications, the connection must be as seamless as possible to prevent “vacuum leaks.” High-performance belts often utilize a hidden clipper seam or a specialized overlap joint that maintains the same thickness as the rest of the belt, ensuring a smooth pass over the vacuum suction boxes.

Conclusion: Maximizing ROI

While a wear-resistant vacuum belt filter cloth may require a higher initial investment, the Return on Investment (ROI) is realized through fewer belt changes, lower labor costs, and higher-quality gypsum production. By focusing on high-permeability vacuum belt filter cloth and chemical compatibility, you ensure your FGD system runs at peak efficiency 24/7.