Maximizing Mining Efficiency with High-Performance Filter Press Cloths

Release time: 2026-01-21

In the global mining sector, from the copper belts of Chile to the lithium projects in Australia, profitability often hinges on the efficiency of the dewatering process. While the filter press is the engine, the mining filter press cloth is the critical component that dictates performance. For procurement officers and plant managers, selecting the right cloth is not just a maintenance task—it is a strategic decision to optimize yield and reduce downtime.

This guide explores the technical aspects of high-performance filter cloths designed specifically for the rigorous demands of the mining industry.

The Core Challenge: Abrasion and Blinding

Mining slurries are notoriously aggressive. High solid content, jagged particle shapes, and varying pH levels create a hostile environment for filtration media. The two most common failure points identified by global operators in the last quarter are

- Premature Wear: Caused by the high velocity of abrasive slurries.

- Blinding (Clogging): Where fine particles become trapped in the weave, drastically reducing filtration rates.

To combat these, leading manufacturers are moving beyond standard textiles, focusing on advanced polymer engineering.

Decoding Product Quality Through Parameters

You don’t need to rely on generic quality labels to judge a filter cloth; the technical specifications speak for themselves. High-quality mining filter cloths are defined by specific physical properties that ensure longevity and cake release.

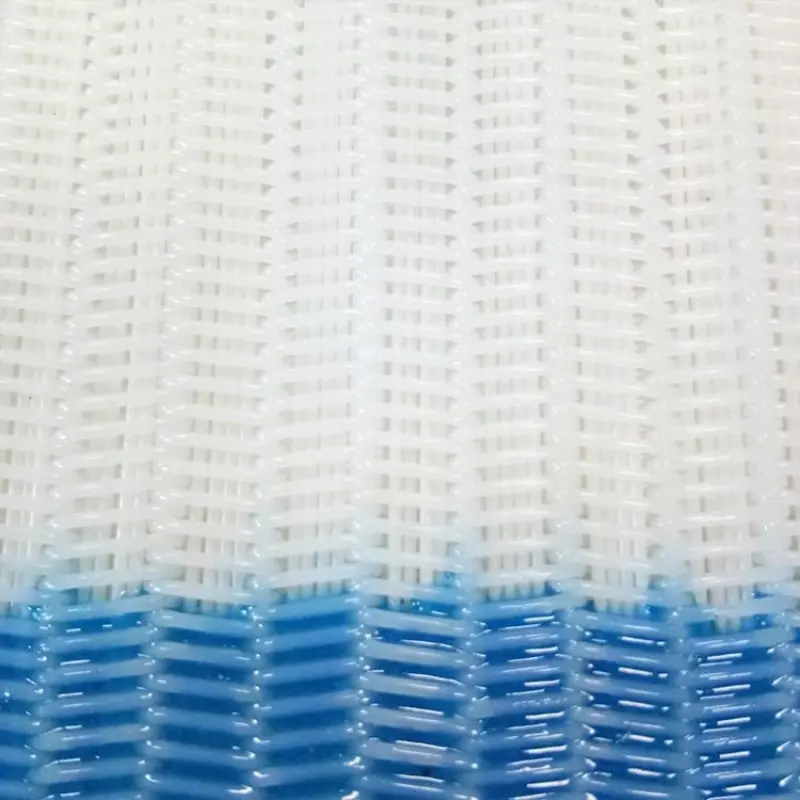

1. Yarn Construction: Mono vs. Multi For heavy-duty mining applications, the trend is shifting towards monofilament and multifilament hybrid weaves.

- Monofilament yarns provide smooth surfaces, ensuring excellent cake release and reducing the need for frequent washing.

- Multifilament yarns offer the tensile strength required to withstand high operational pressures (often exceeding 16 bar in modern presses).

- Tip: Look for cloths that utilize a “double-layer” weave design to balance retention accuracy with drainage speed.

2. Weave Patterns and Abrasion Resistance The weave pattern determines how the cloth handles friction.

- Satin Weave: Offers the smoothest surface for the easiest cake discharge, ideal for sticky tailings.

- Twill Weave: Provides a denser structure, offering superior resistance to mechanical wear and blinding.

3. Vital Specs to Check When evaluating a manufacturer’s data sheet, focus on these metrics:

- Air Permeability: Measured in L/dm²/min. A consistent permeability rating ensures stable cycle times.

- Breaking Strength: High N/5cm ratings indicate the cloth’s ability to resist tearing under high feed pressures.

- Heat Setting: A quality cloth must undergo rigorous heat setting processes to ensure dimensional stability, preventing the cloth from stretching or shrinking during operation.

Customization: One Size Does Not Fit All

A “universal” filter cloth is a myth in the mining industry. The optimal solution depends on your specific concentrate or tailing characteristics.

- For Fine Gold/Copper Tailings: High particle retention is a priority. A tightly woven cloth with calendering treatment helps capture fine microns while maintaining flow.

- For Coal Washing: Moisture reduction is key. Utilizing hydrophobic materials like specialized polypropylene (PP) can significantly lower the final cake moisture content, saving transport costs.

Sourcing from the Right Manufacturer

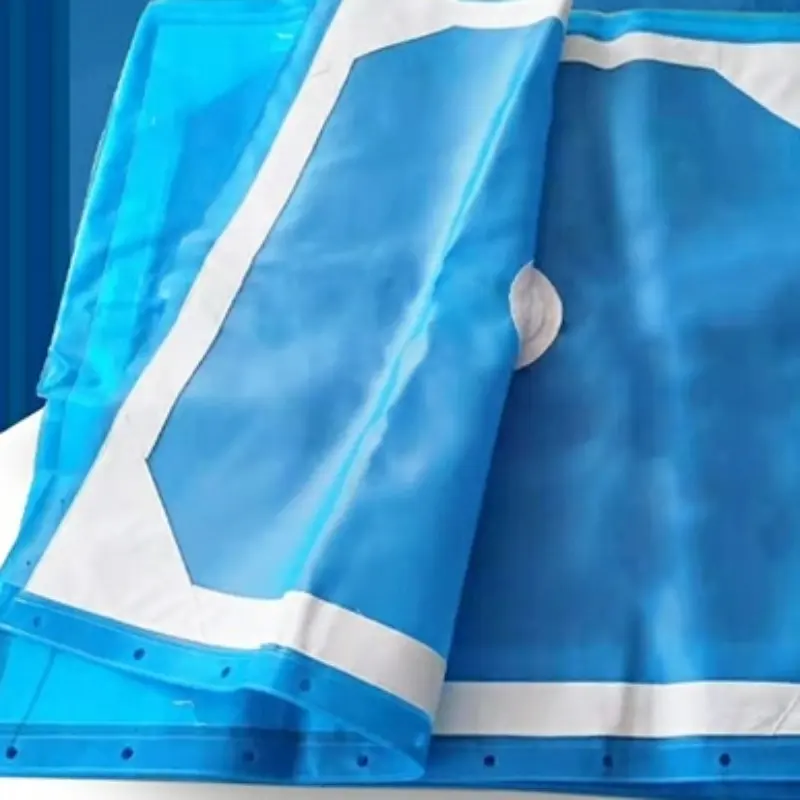

In the B2B landscape, the difference between a vendor and a partner is their understanding of your slurry. Top-tier manufacturers do not just sell rolls of fabric; they offer laser-cutting technology for precision fit (ensuring zero leakage at the sealing edges) and provide technical consultations based on slurry analysis.

When sourcing, prioritize factories that can demonstrate strict control over raw material selection and weaving consistency. The ability to customize the neck material (often the first point of failure) with rubberized or reinforced coatings is a hallmark of a high-quality production line.

Conclusion

Upgrading your mining filter press cloths is one of the most cost-effective ways to boost plant capacity. By focusing on technical parameters like yarn construction, weave stability, and abrasion resistance, you can extend the lifecycle of your consumables and ensure your filter press operates at peak efficiency.