Como trocar o tecido da prensa de filtro? Guia profissional e dicas práticas.

Data de lançamento: 26/09/2025

Índice

Na indústria de separação sólido-líquido, a eficiência operacional de uma prensa de filtro está intimamente ligada ao desempenho do tecido filtrante. Quando o equipamento apresenta uma diminuição na velocidade de filtração, um aumento no teor de umidade da torta de filtração ou uma qualidade de filtração instável, geralmente significa que o tecido filtrante precisa ser substituído imediatamente. Muitas empresas, especialmente fábricas que utilizam telas filtrantes para prensas de filtro de correia, telas para prensas de filtro de placas e molduras ou telas filtrantes de poliéster de alta resistência, têm grande preocupação com a questão: "Como trocar o tecido filtrante da prensa de filtro?". Xurui explicará em detalhes as etapas operacionais e as precauções para a troca do tecido filtrante, ajudando você a melhorar a estabilidade do equipamento e a eficiência da produção.

Preparação: Garantindo Segurança e Precisão

Antes de iniciar a troca do tecido filtrante, a prensa de filtro deve ser desligada, a energia desconectada e a pressão liberada. Para usuários que utilizam tecido filtrante para prensa de filtro de correia para desidratação de lodo industrial, a câmara de filtragem e os pratos filtrantes também devem ser limpos para garantir que nenhum resíduo de lodo interfira na instalação. Verificar se a superfície do prato filtrante está plana e livre de desgaste ou danos também é uma etapa crucial.

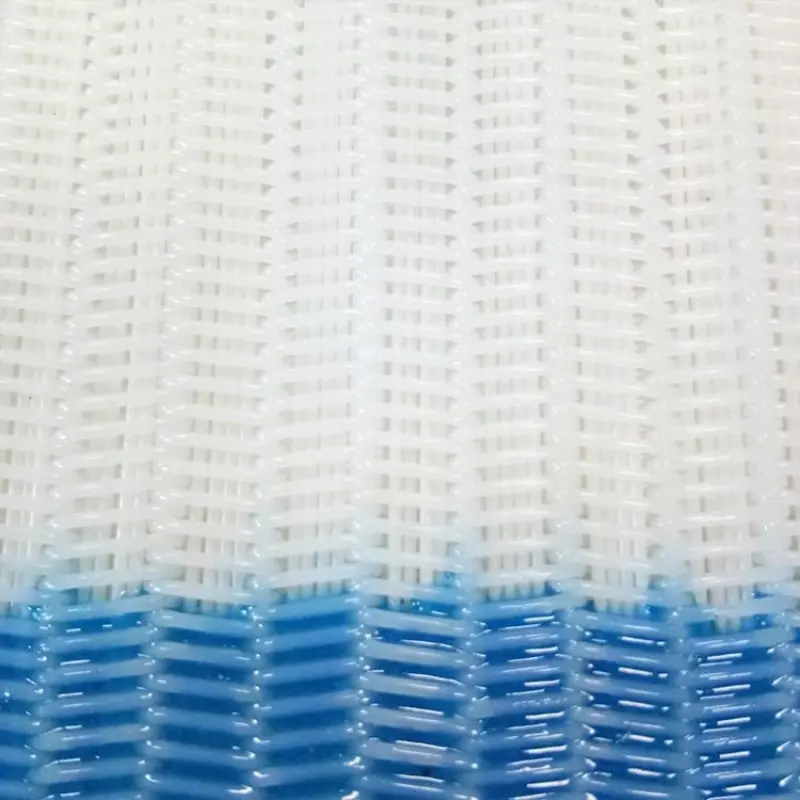

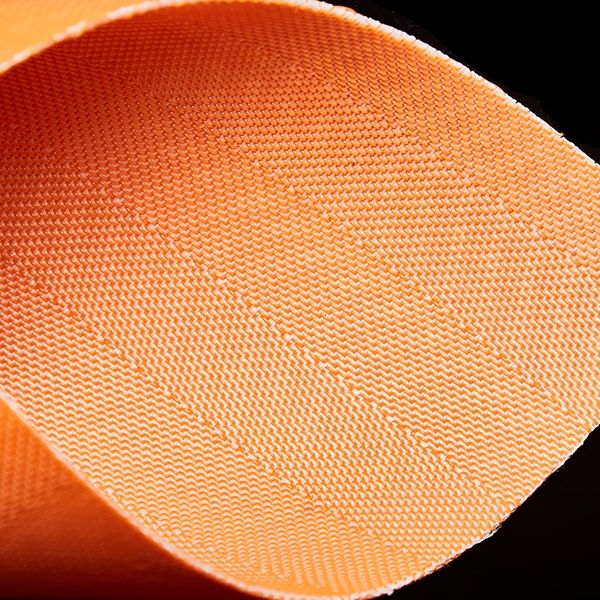

Ao preparar um novo tecido filtrante, certifique-se de que seu material, gramatura, permeabilidade ao ar e tamanho correspondam ao equipamento original. Por exemplo, comumente panos de filtro prensa de polipropileno Os tecidos para filtros prensa de correia resistentes a ácidos/álcalis têm diferentes aplicações adequadas; escolha sempre de acordo com as recomendações do fabricante do equipamento ou do engenheiro.

Removendo o tecido filtrante antigo: Mantendo a integridade da placa do filtro

Após abrir completamente o equipamento, o tecido filtrante antigo pode ser removido pedaço por pedaço. Evite cortes diretos com objetos pontiagudos durante a remoção para não arranhar as bordas de vedação da placa do filtro. Se o tecido filtrante antigo estiver muito incrustado, use uma pistola de água ou ferramentas para auxiliar na limpeza da superfície da placa do filtro. Esta etapa é particularmente importante para sistemas que utilizam [informação faltante]. telas de filtro prensa de correia para tratamento de águas residuaispois partículas duras no lodo podem criar pontos de dano sob o tecido filtrante.

Instalação do novo tecido filtrante: Garantindo o alinhamento e a vedação

Ao instalar o novo tecido filtrante, alinhe o orifício central do tecido com o orifício de alimentação da placa filtrante para garantir o posicionamento correto. Alise o tecido filtrante nas bordas para que fique bem ajustado à superfície da placa filtrante, evitando rugas que possam causar vazamentos. Em filtros prensa de correia, é fundamental verificar a tensão do tecido filtrante para garantir a uniformidade em ambos os lados e evitar deslocamentos durante a operação.

Muitos usuários optam por telas filtrantes de alta permeabilidade para filtros de correia, pois permitem uma descarga mais rápida do filtrado e facilitam a remoção da torta de filtração. No entanto, independentemente do tipo de tela filtrante escolhida, o equipamento deve ser girado manualmente após a instalação para verificar se há algum travamento, atrito ou deslizamento.

Teste e Inspeção

Após instalar o novo tecido filtrante, inicie o equipamento para um teste de funcionamento em baixa pressão. Verifique se o filtrado está límpido, se há vazamentos laterais e se o tecido filtrante se move normalmente. Se a operação estiver estável, aumente gradualmente a pressão até a faixa normal de operação.

Em cenários onde são utilizadas telas filtrantes resistentes ao desgaste para prensas de filtro de correia, como na desidratação de lamas, a tensão pode ser ajustada adequadamente para manter a tela filtrante estável sob cargas elevadas.

Dicas para prolongar a vida útil do tecido filtrante

Limpe o tecido do filtro regularmente para evitar entupimentos.

Controle a concentração da ração e a distribuição das partículas.

Utilize um sistema de descarga adequado.

Evite operação prolongada com sobrepressão.

Resumo

A substituição do tecido filtrante é uma etapa importante para garantir o funcionamento eficiente do equipamento e prolongar sua vida útil. A desmontagem, instalação e manutenção adequadas podem melhorar significativamente a eficiência da filtração e reduzir as taxas de falha do equipamento. Ao selecionar um novo tecido filtrante, escolha tecidos adequados para filtros prensa de correia, como... panos filtrantes de poliéster de alta resistência ou telas filtrantes resistentes a ácidos e álcalis, dependendo do tipo de equipamento e do ambiente de trabalho, para garantir o desempenho ideal da filtração. A limpeza e a manutenção regulares das telas filtrantes, evitando a sobrecarga, são maneiras eficazes de prolongar sua vida útil. Seguindo essas etapas, a eficiência de trabalho da prensa de filtro pode ser efetivamente melhorada, garantindo a estabilidade e a economia do processo de produção.