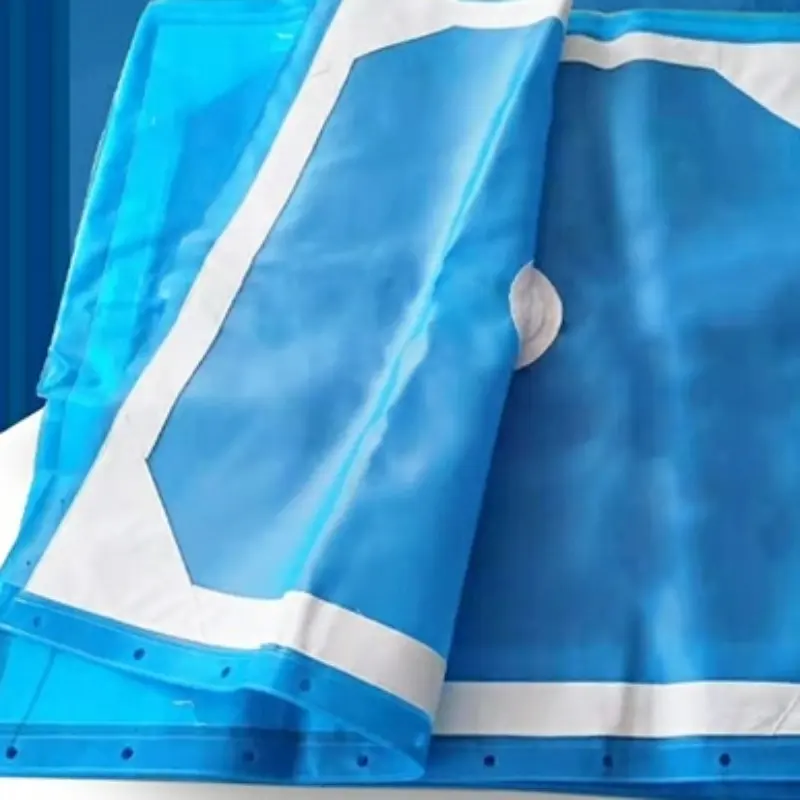

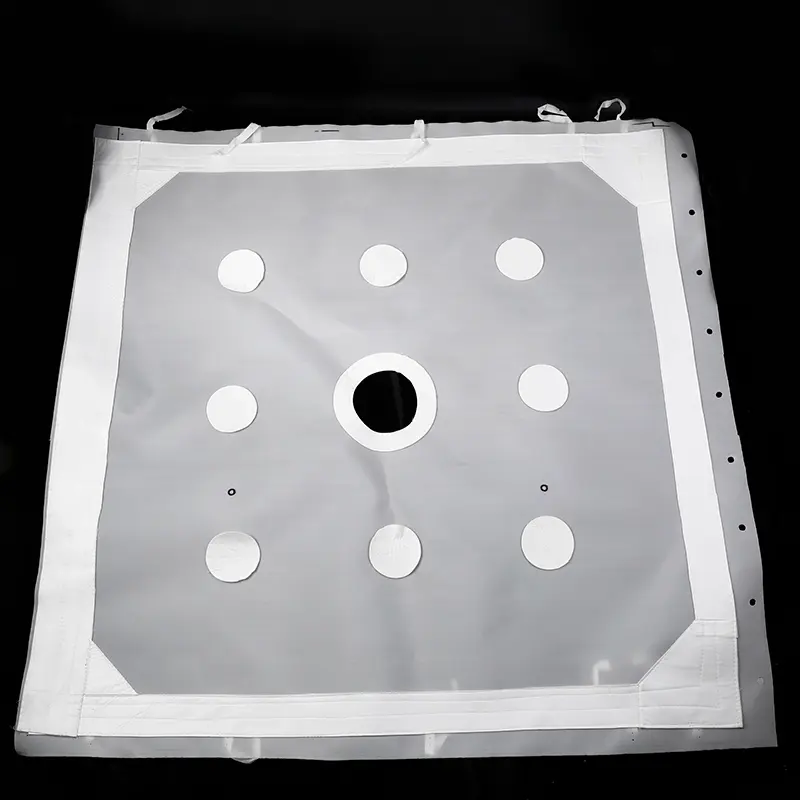

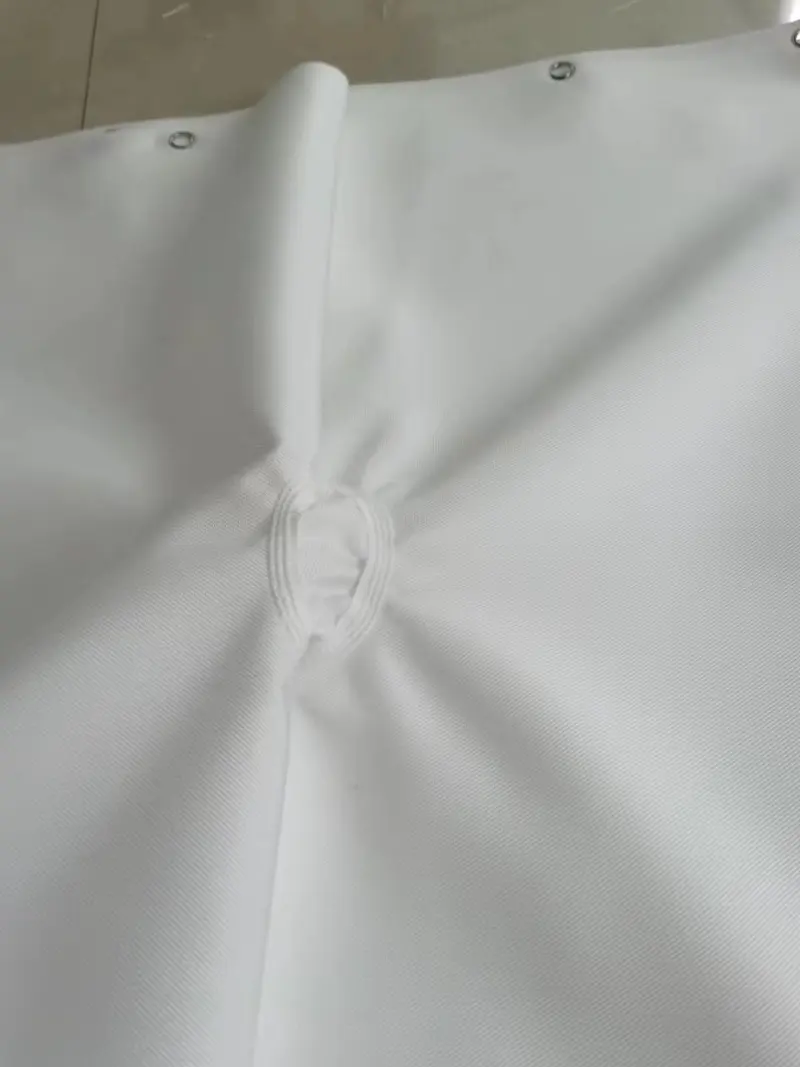

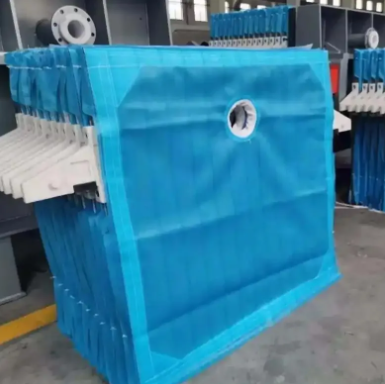

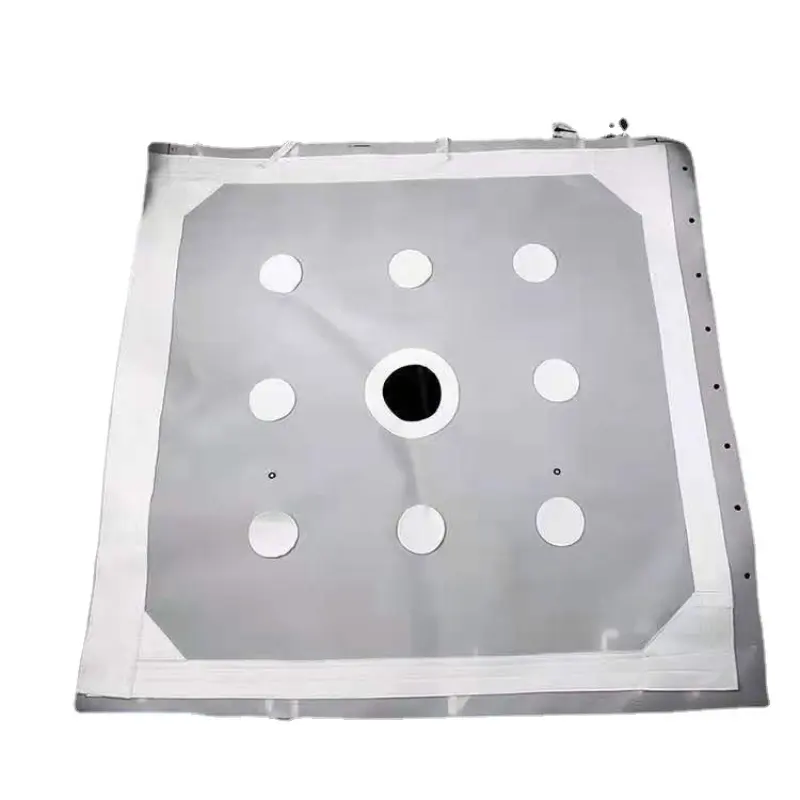

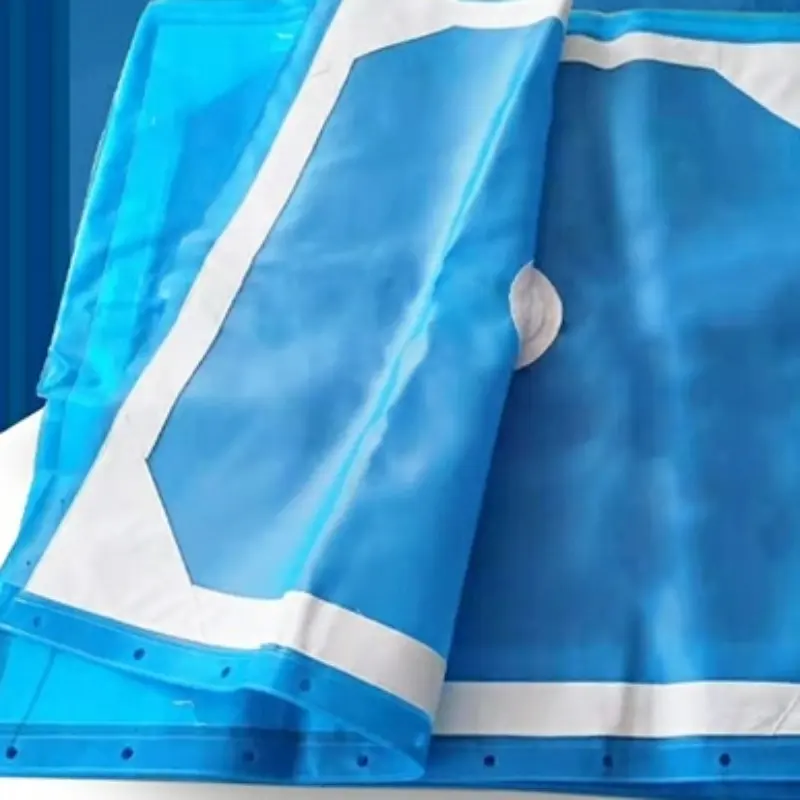

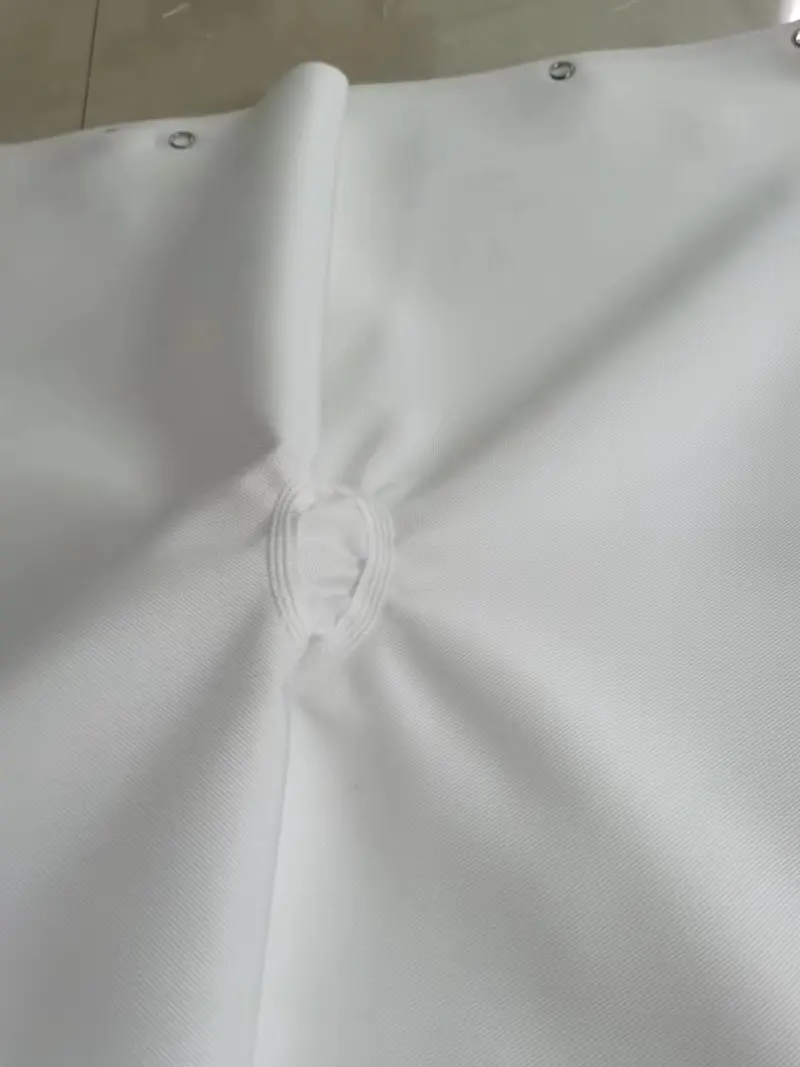

Filter Cloth for Press Filter Machine

Filter press cloth plays the role of filtering and separating solid-liquid mixtures in the filter press. Its quality and performance directly affect the working efficiency and filtering effect of the filter press. The filter cloth allows liquid to penetrate through tiny pores, while trapping solid particles on the surface of the filter cloth to form a filter cake. During the operation of the filter press, the filter cloth needs to withstand high pressure and have good water permeability and wear resistance to ensure a smooth filtering process.

There are various types of filter cloth for filter presses. Depending on different filtering requirements and operating environments, the weaving method, thickness, pore size and surface treatment of the filter cloth are different. Common types of filter cloth include plain weave filter cloth, twill filter cloth and needle-punched filter cloth. Plain weave filter cloth is suitable for general filtering needs, while twill filter cloth is more commonly used in high-precision filtering occasions because of its smooth surface and easy de-cake. Needle-punched filter cloth is made by needle-punching process, and its surface presents a fiber mesh structure. It has stronger air permeability and water filterability, and is suitable for filtering high-concentration solid-liquid mixtures.

Features of filter press machine:

1. Filter frame is made of high quality Q235 Carbon Steel. Have a large structure strength, stable performance and higher quality.

2. Filter plates are made of strengthened polypropylene, and adopt international advanced TPE membrane technology, so have high in strength, light in weight, corrosion resisted, non-poisonous and odorless.

3. Hydraulic unit, China brand famous pumps and hydraulic valve. High squeeze pressure.

4. Electric control cabinet, PLC control cabinet with Siemens brand or brand Electrical components, Split type or can be fixed on the beam.

5. Easy to operate, lower running cost,safe and reliable.

6. Can realize automatic clean filter clothes.

7. High automation and save labour.

8. Reduce filtration time and shorter cycle time.

9. Lower filter cakes moisture and easy to discharge filter cakes.

10. Sealing better. No leakage to avoid secondary pollution.

Filter press filter cloth is usually made of synthetic fiber and natural fiber. Synthetic fiber is widely used in chemical, metallurgical, pharmaceutical and other industries due to its good chemical stability, acid and alkali resistance and strength. Polypropylene filter cloth is widely used in industrial wastewater treatment, chemical material filtration and other fields due to its acid, alkali and corrosion resistance. Polyester filter cloth has good wear resistance and high temperature stability and is often used for filtering high temperature materials. Natural fiber filter cloth is mostly used in food processing, pharmaceutical and other fields that require high material purity.

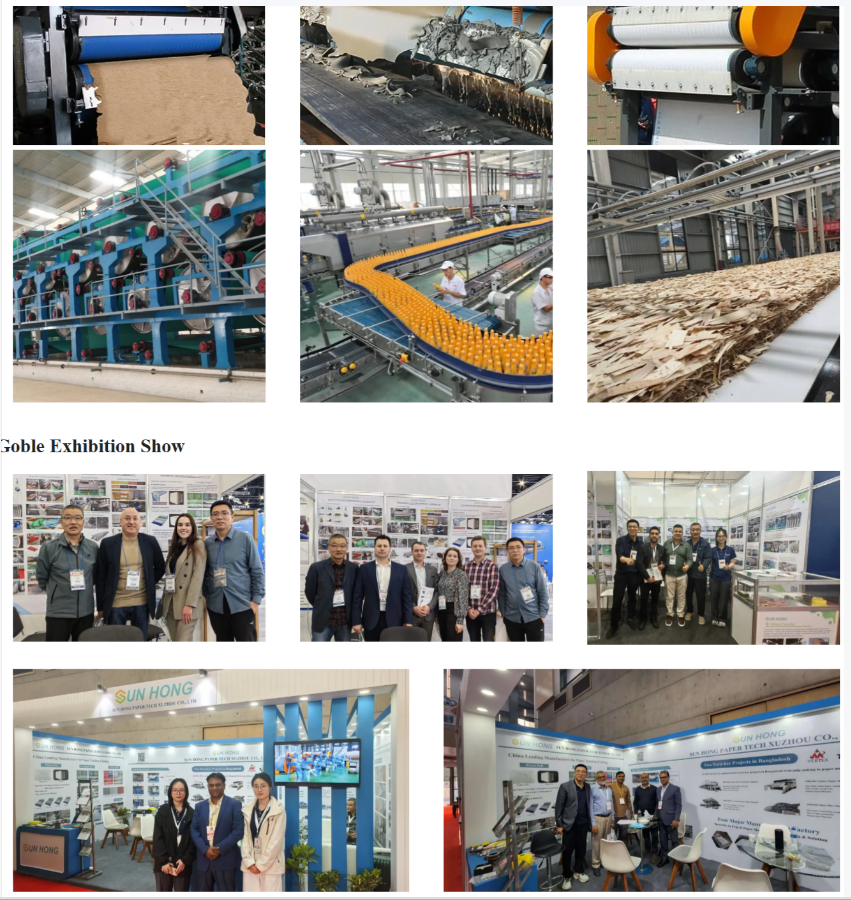

XURUI manufacturer high quality mesh belt for different industry application and machine, such as juice press, belt filter press, horizontal vacuum belt filter, food drying machine, paper machine, artificial board pavement machine, dryer paper machine, non-woven equipment, etc. Welcome to contact us to get suitable belt.

Application area:

Related Products

Related Products