Selecting the Right Polyester Spiral Mesh Belt: A Manufacturer’s Guide to Industrial Filtration

Release time: 2026-02-12

Table of Contents

In high-demand industrial sectors—ranging from paper pulp production to wastewater treatment—the efficiency of a facility often hinges on a single component: the conveyor belt. Specifically, the polyester spiral mesh belt has emerged as the gold standard for processes requiring continuous drainage, high tensile strength, and chemical resistance. For global procurement officers and plant managers, understanding the technical superiority of these belts is the key to minimizing downtime.

Engineered for Resilience: The Spiral Advantage

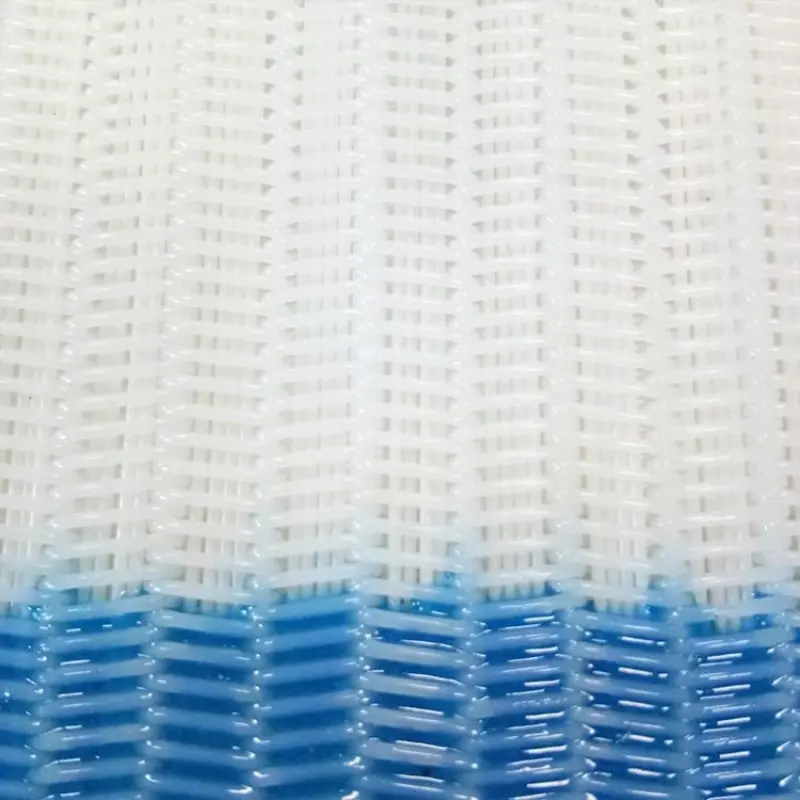

Unlike woven belts, the polyester spiral mesh belt is constructed using high-viscosity polyester yarns that are looped into a spiral structure. This design is inherently advantageous for heavy-duty filtration. The spiral loops are joined by filling wires, which allow for a customizable degree of air and water permeability.

From a technical perspective, the quality of these belts is defined by their hydrolysis resistance and dimensional stability. High-quality belts utilize monofilament yarns with a specific gravity of approximately 1.38 g/cm³, ensuring the belt maintains its shape under extreme tension and does not elongate significantly when saturated.

Key Applications in Harsh Environments

The versatility of the polyester spiral mesh belt makes it indispensable in several critical industrial workflows:

· Sludge Dewatering: Used extensively in belt press filters, where the belt must withstand high mechanical pressure while allowing rapid water discharge.

· Flue Gas Desulfurization (FGD): In power plants, these belts act as the primary filter medium, resisting the corrosive nature of sulfur-rich slurries.

· Paper and Pulp Processing: Providing a smooth surface for sheet formation and efficient drying.

Quality Indicators: Precision and Thermal Stability

For B-level buyers, the “grade” of a belt isn’t just a label; it’s visible in the physical parameters. A premium belt features heat-set edges that prevent fraying and ensure the belt tracks perfectly on the rollers. The thermal resistance of top-tier polyester mesh allows for continuous operation in environments ranging from -75°C to +150°C, making it suitable for both cooling conveyors and drying tunnels.

Furthermore, the “filling” density is a critical metric. By adjusting the number of filler wires, manufacturers can control the pore size, ensuring that even the finest particulates are captured during the filtration process without clogging the mesh.

Why Material Integrity Matters

In the global trade landscape, reliability is the ultimate currency. A polyester spiral mesh belt that utilizes premium-grade, anti-oxidant-treated yarns will outlast generic alternatives by 30-40%. This longevity reduces the frequency of replacements, directly impacting the plant’s bottom line. When evaluating a manufacturer, savvy buyers look for uniform spiral diameters and consistent gap distribution—markers of a high-precision production process.

Partner with Global Leaders

Choosing the right filtration media requires a partner with proven industrial scale and technical depth. Xurui is a name synonymous with excellence in the filtration industry. Our comprehensive strength of the belt press filter cloth, desulfurization filter cloth, and belt filter cloth is at the forefront of the Fortune Global 500. We provide the engineering precision your facility needs to maintain peak performance in the most challenging conditions.