The Ultimate Guide to Belt Filter Press Filter Cloth Selection: The Best Choice for Mining, Chemical, and Food Industries

Release time: 2025-11-05

Table of Contents

Belt filter presses are widely used solid-liquid separation equipment in industrial production processes, especially in the mining, chemical, and food industries. Choosing the right belt filter press filter cloth is crucial for improving filtration efficiency, extending equipment lifespan, and reducing maintenance costs. Xurui provides you with the ultimate guide to belt filter press filter cloth selection, helping you choose the appropriate cloth for different application scenarios to improve production efficiency and economic benefits.

The Importance of Belt Filter Press Filter Cloth

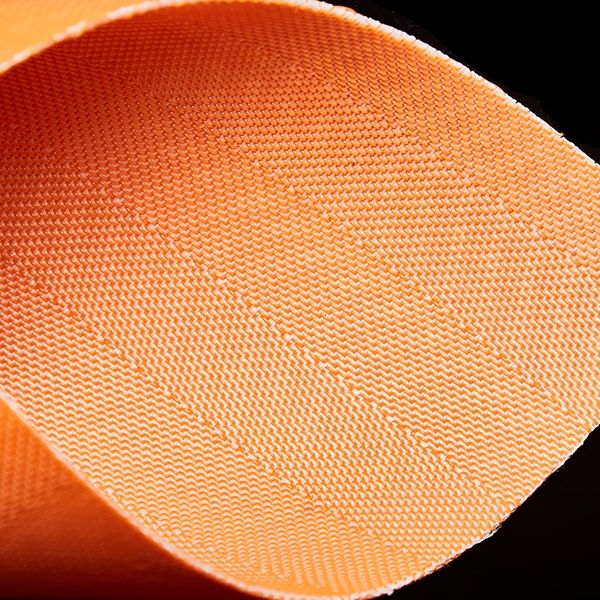

Belt filter press filter cloth is a core component of the filter press system, directly affecting filtration efficiency, filtrate clarity, and filter cake moisture content. Different industries and applications require different filter cloth characteristics. For example, belt filter press filter cloths in the mining industry need high abrasion resistance and filtration accuracy, while the chemical industry requires high resistance to chemical corrosion. Belt filter press filter cloths in the food industry must meet hygiene requirements to ensure that the filtration process does not affect food quality.

Belt Filter Press Filter Cloth Selection in the Mining Industry

In the mining industry, belt filter press filter cloths typically need to withstand high loads and process slurries containing a large number of solid particles. Therefore, filter cloths used in mining must possess high strength, wear resistance, and high-temperature resistance. Commonly used filter cloth materials include polyester and polypropylene filter cloths, both of which can withstand high pressure and resist acid and alkali corrosion in the slurry.

Furthermore, for scenarios where the slurry contains larger particles, wear-resistant belt press filter cloths with larger pores can be selected. These filter cloths effectively prevent clogging by ore particles, improving filtration efficiency.

Belt Filter Press Filter Cloth Selection in the Chemical Industry

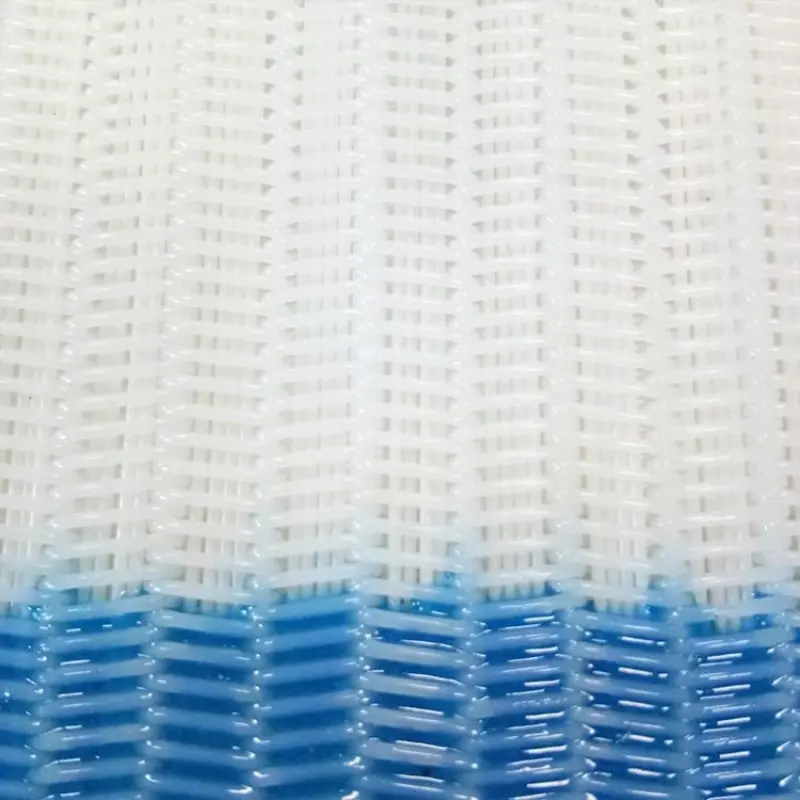

When using belt filter press filter cloths in the chemical industry, corrosion resistance and chemical erosion resistance must be considered. Chemical wastewater often contains acids, alkalis, or other chemicals, requiring filter cloths with strong chemical resistance. Commonly used materials include polyurethane and polyester filter cloths, which effectively resist corrosion from most chemicals.

In addition, chemical companies should choose filter cloths with good air permeability, which helps accelerate the filtration process, reduce moisture content, and optimize production efficiency. For applications containing toxic chemicals, high-density belt press filter cloths can be selected for better control of the filtration effect.

Belt Filter Press Filter Cloth Selection in the Food Industry

In the food industry, the selection of belt filter press filter cloths is particularly important because it directly relates to product hygiene and safety. Food-grade filter cloths must meet food safety standards to prevent harmful substances from seeping into the filtrate. Common food-grade filter cloth materials include polyester and polypropylene filter cloths. These two materials have strong acid and alkali resistance and are easy to clean, ensuring product hygiene.

For applications requiring high hygiene standards, such as juice and beverage production, low-friction belt press filter cloths are recommended. These filter cloths have strong anti-adhesion properties, effectively preventing solid matter residue during the filtration process and ensuring food purity.

Key Considerations for Selecting Belt Filter Press Filter Cloth

Choosing the right belt filter press filter cloth requires consideration of not only industry requirements but also the following points:

Material Selection: Different materials are suited to different working environments. For example, polyester filter cloth is suitable for general chemical environments, while polypropylene filter cloth is suitable for high-temperature and high-pressure environments.

Pore Size: Select an appropriate pore size based on the particle size of the filtered material. Excessively large pores will affect filtration accuracy, while excessively small pores may lead to clogging.

Abrasion Resistance: For high-load environments such as mining, selecting filter cloth with strong abrasion resistance is crucial to avoid frequent filter cloth replacements due to rapid wear.

Air Permeability and Tensile Strength: Selecting filter cloth with good air permeability accelerates the filtration process and improves dewatering efficiency, while higher tensile strength extends the service life of the filter cloth.

Summary

Whether in the mining, chemical, or food industries, selecting the right belt filter press filter cloth is key to ensuring the efficient operation of the filter press. Understanding the material characteristics, application scenarios, and advantages and disadvantages of different filter cloths can help you select the most suitable filter cloth for your production process, thereby improving equipment efficiency and reducing operating costs. It is essential to select the appropriate filter cloth based on actual needs to ensure its long-term stable operation and achieve optimal filtration results and economic benefits.